THIS ARTICLE/PRESS RELEASE IS PAID FOR AND PRESENTED BY SINTEF - read more

Do we need to sacrifice nature in the fight against climate change?

Today, key minerals and metals are being transported to Europe from politically unstable countries far away. Is it possible to safeguard access to these raw materials here in Norway?

Minerals and critical raw materials are playing a key role in the development of renewable energy and other technologies that we need for future growth.

But how, and from where, should we obtain these valuable raw materials in the future?

At present, massive amounts of raw materials are being transported to Europe from the other side of the world.

“From an environmental, societal and commercial perspective, this is indefensible. Instead, we should be getting our act together and look into how we can obtain the resources here in Europe in an environmentally and climate-friendly way,” Nils Anders Røkke says.

He is SINTEF's executive vice president for sustainability.

Demand will increase

Critical raw materials are defined as materials that are commercially important for global economic growth, but which also entail high levels of risk linked to access or supply.

The EU operates with a list of such critical raw materials where we find metals like cobalt, lithium and the rare-earth elements (REEs).

Access to all of these is crucial for the expected growth of green energy technologies during the next 20 years.

According to the International Energy Agency (IEA), we will require 42 times more lithium than is currently being consumed, while the demand for REEs will increase by 7 times.

Today, our access to these materials depend entirely on import.

Securing access and reducing dependency

How can we address these complex challenges and at the same time maintain ecological sustainability and mitigate climate change?

SINTEF is one of the research institutes that are looking into ways of meeting the growing demand for minerals and critical raw materials.

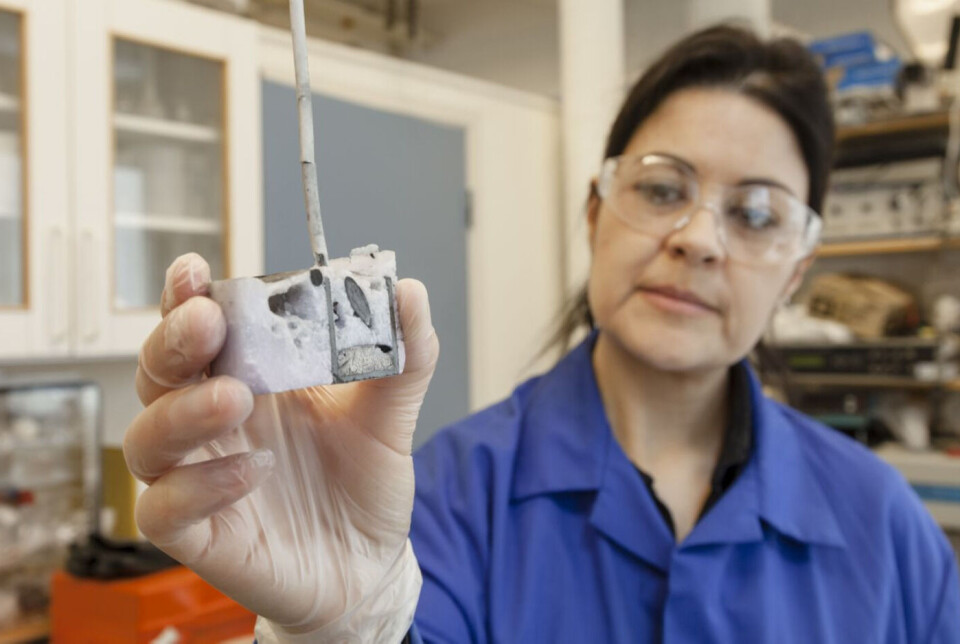

Ana Maria Martinez is a research scientist at SINTEF who works on developing innovative and enviornmentally-friendly technologies designed to recover critical raw materials from mineral deposits (primary sources) and discarded end-of-life and by-products (secondary sources). One example is making new solar panels from solar cell waste.

In broad terms, Martinez is looking into three strategies designed to safeguard access to, and reduce our dependence on, critical raw materials.

1. More sustainable mining and extraction

China is currently the world’s largest supplier of REEs, while Congo furnishes between 60 and 70 per cent of the world’s cobalt. Russia also extracts a large proportion of cobalt.

Simultaneously, global climate change mitigation policies are being tightened. Recently introduced climate change legislation in the USA is creating obstacles to the EU and Norway’s access to both primary minerals and manufactured batteries.

“The achievement of Europe’s ambitious energy and climate mitigation targets is highly dependent on supplies of raw materials currently being imported from geopolitically unstable countries,” Martinez says.

She explains that reductions in exports of critical raw materials from these countries will put the green transition at risk. We have to increase the rates of extraction of these minerals both in Norway and Europe as a whole.

"We must do everything we can to achieve self-sufficiency in critical raw materials and to support the value chains in which the most important of them circulate,” she says.

However, the situation is not all bad.

Extraction in Norway is possible

Norway has several mineral deposits and a number of mines currently in operation, although none that are relevant to the extraction of critical raw materials.

Norway also has deposits containing REEs, the most important being the FENS field in Telemark, southern Norway.

Exploration and mapping of the FENS field is being carried out to appraise the types of minerals present and their extent.

No mining is currently taking place, but the field may represent a key resource for both Norway and Europe in the future.

Mining and extraction in Norway will contribute towards meeting some of the demand for critical raw materials, but will be nowhere near sufficient to meet overall increases in need.

Explore the seabed

“The war in Ukraine has demonstrated how dependent we are on imports from politically unstable countries, how easy it is for key value chains to be seriously disrupted, and how vulnerable our European economic model is. We have to identify new methods of extracting these metals that are both eco-friendly and sustainable,” Martinez says.

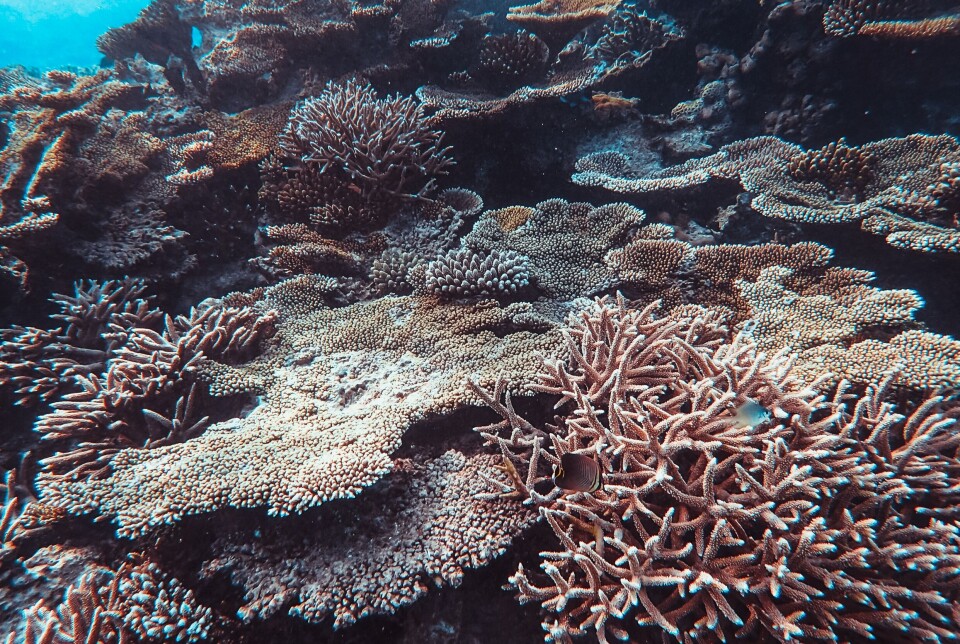

One solution may be to explore the deep seabed. But this is controversial. Is it possible to recover these minerals in ways that do not harm existing ecosystems?

There are large deposits of minerals and raw materials on the seabed. The metals involved include copper and manganese, magnesium and cobalt, as well as rare-earth elements such as neodymium and dysprosium.

These are used to manufacture the magnets installed in wind turbines and electric vehicle engines.

Can it be extracted?

One thing is certain: At present we know far too little about the potential impact that seabed mining may have on climate and the environment.

Research Director Lars Sørum says that we need a combination of more knowledge and new technologies that will enable us to decide whether or not seabed mining is harmful to marine ecosystems.

Preliminary sampling has demonstrated that the concentration of metals in seabed deposits is much greater than on land.

"If it becomes possible to extract these efficiently and sustainably, it will boost the potential for meeting the green transition’s demands for valuable minerals,” he says.

Less damaging than on land?

“If it emerges that the concentrations of metals in seabed deposits are as high as initial sampling suggests, it may prove to be the case that seabed mining can be more climate- and eco-friendly than extraction on land,” Sørum says.

The prerequisite is that it is possible to extract seabed minerals in a sustainable way.

Expertise and technologies from the oil and gas and onshore mining industries give Norway a competitive advantage when it comes to developing climate- and eco-friendly systems for seabed mining.

Targeted investment needed

SINTEF possesses broad expertise and a leading position in terms of technology development in the oil and gas sector. Know-how and technologies in the fields of drilling, processing and, not least, environmental knowledge, are some of the areas of knowledge SINTEF applies to seabed mining.

“We are currently looking into concepts that can perform mining operations in ways that are sensitive to seabed ecosystems. This work will require an examination of the entire value chain. In particular, we want to look into how we can use boreholes and the return of drilled materials to enable the sensitive protection of ecosystems during extraction of the rock material,” Sørum says.

But developing this expertise will not happen overnight.

"Targeted investment in research and development is required," he says.

2. Recycle and reuse

Since the demand for materials and minerals is so great, we need more than one leg to stand on. As well as mining from primary sources, we must also reclaim materials from secondary sources, which means recycle and reuse them.

This was also announed in the Norwegian government’s new mineral strategy. A current buzzword is ‘urban mining’.

“We must exploit our resources as best we can. Urban mining is all about recovering raw materials from existing end-of-life products, buildings and other waste. If we repair existing products, and recycle and reuse materials and minerals, we will be able to significantly reduce both the energy consumption and carbon footprint, and to counteract the negative impacts of primary production,” Ana Martinez says.

A key source of rare-earth elements is electronic waste.

As part of the EU-financed project REEPRODUCE, SINTEF’s researchers are looking into how we can remove magnets from end-of-life products and recover the REEs that they contain in eco-friendly and cost-effective ways.

Rare-earth elements in Europe

Another approach is to investigate the production of fertiliser.

There are many REEs are in circulation in this industry. The SecREEts project is investigating the extraction of REEs from European sources of apatite.

“The biggest end users of REEs are industries that manufacture the magnets used in electric vehicles to make their engines more efficient," Matinez says.

They are also used in renewable energy technology, such as in offshore wind turbines.

“Today, Europe is entirely dependent on imports for its supplies of REEs, and there are no clear substitutes on the market. This is why it is important to establish a stable and secure European value chain for REEs,” she says.

3. New products involving less or no critical raw materials

In order to minimise the carbon footprint of a new product, the raw materials used in its manufacture must be sourced as close as possible to the site of manufacture. Thus, raw materials derived from secondary sources should ideally be sourced locally.

Another means of achieving our target is simply to develop new products and technologies that use less critical raw materials than at present.

“We are involved in several projects that are looking into reducing, or eliminating entirely, our dependence on critical raw materials in connection with key technologies linked to the green transition, such as batteries. This involves examining the entire life cycle of the product, taking both economics and sustainability into account ,” says Martinez.

The HYDRA and InteLiGent projects are good examples. Here, more efficient, and commercially profitable batteries are being developed that are cobalt-free, and which make use of more sustainable and more easily accessible raw materials. Both of these projects are funded by the EU with the aim of developing lithium-ion batteries for electric vehicles.

The government's mineral strategy

“Lithium is also defined as a critical raw material, sourced for the most part from Australia and South America. Even though lithium remains an essential component in lithium-ion batteries, the amounts we use can be reduced significantly either by means of smart materials selection or the application of alternative battery technologies,” Martinez says.

The Norwegian government is currently preparing a new minerals strategy with the aim of promoting development of the world’s most sustainable minerals industry.

“We are well underway in terms of the know-how, methods and technology development we will need to make this possible. However, we currently know too little about how we can recover minerals from the seabed while keeping the marine ecosystems intact. To achieve this, we will need more research and development. We need to develop technologies that can make mineral extraction possible. If we succeed, there will be major opportunities to extract minerals from the seabed,” Nils Anders Røkke says.

See more content from SINTEF:

-

300 meals can be saved from this kitchen – every month

-

Saving seagrass and French oysters: New solutions give new life to Europe's coastal areas

-

What does ultra-processed food do to our gut flora?

-

This new device can make it cheaper to heat your home

-

Propellers that rotate in opposite directions can be good news for large ships

-

How Svalbard is becoming a living lab for marine restoration