THIS CONTENT IS BROUGHT TO YOU BY SINTEF - read more

Testing a giant ship:

May take five kilometres to stop

This is probably unsurprising, as the ship is longer than the Eiffel Tower is tall, 62 metres wide, and will extend 21 metres below the water’s surface.

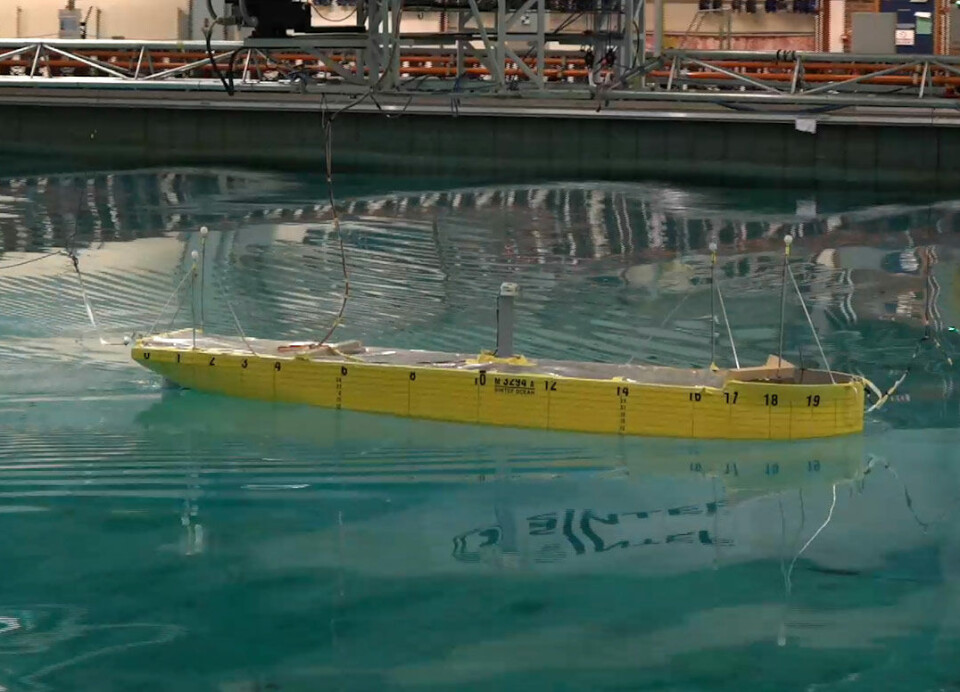

Researchers will now test how the ship behaves at sea using four small models in SINTEF's test pool.

To the untrained eye, it may be difficult to understand how models between five and seven metres can accurately predict how a 333-metre-long ship will behave in open waters. SINTEF can test large ships using small models because they scale down time, speed, and forces.

“It’s challenging and exciting to work with some of the world’s largest ships. A small hull modification and optimisation can have a big impact on fuel consumption,” says project manager at SINTEF Ocean, Toralf Sundin Hamstad.

The hull is the main part of a ship, the part that keeps it afloat.

Will transport iron ore

The new ship, which will transport iron ore from Brazil to China, may take more than five kilometres to stop and 1.6 kilometres to turn.

These are such large dimensions that they almost seem unreal. But large ships on vast oceans can operate with such numbers. They also need tugboat assistance when approaching land to dock or depart.

Here you can see a clip from the tests:

“According to IMO criteria, the ship stopping length should not exceed 15 ship lengths, and tactical turning diameter should not exceed five ship lengths,” says Hamstad.

But before the unusually large cargo ship can be built, SINTEF Ocean need to test how it handles different wave heights and directions, and how the propeller interacts with the hull.

Tested with four models

Four different hull models were used during testing. In calm water, the hull is tested to determine hull resistance.

This is the combined force that resists a vessel's movement through water, and determines how large an engine and propeller the ship will need.

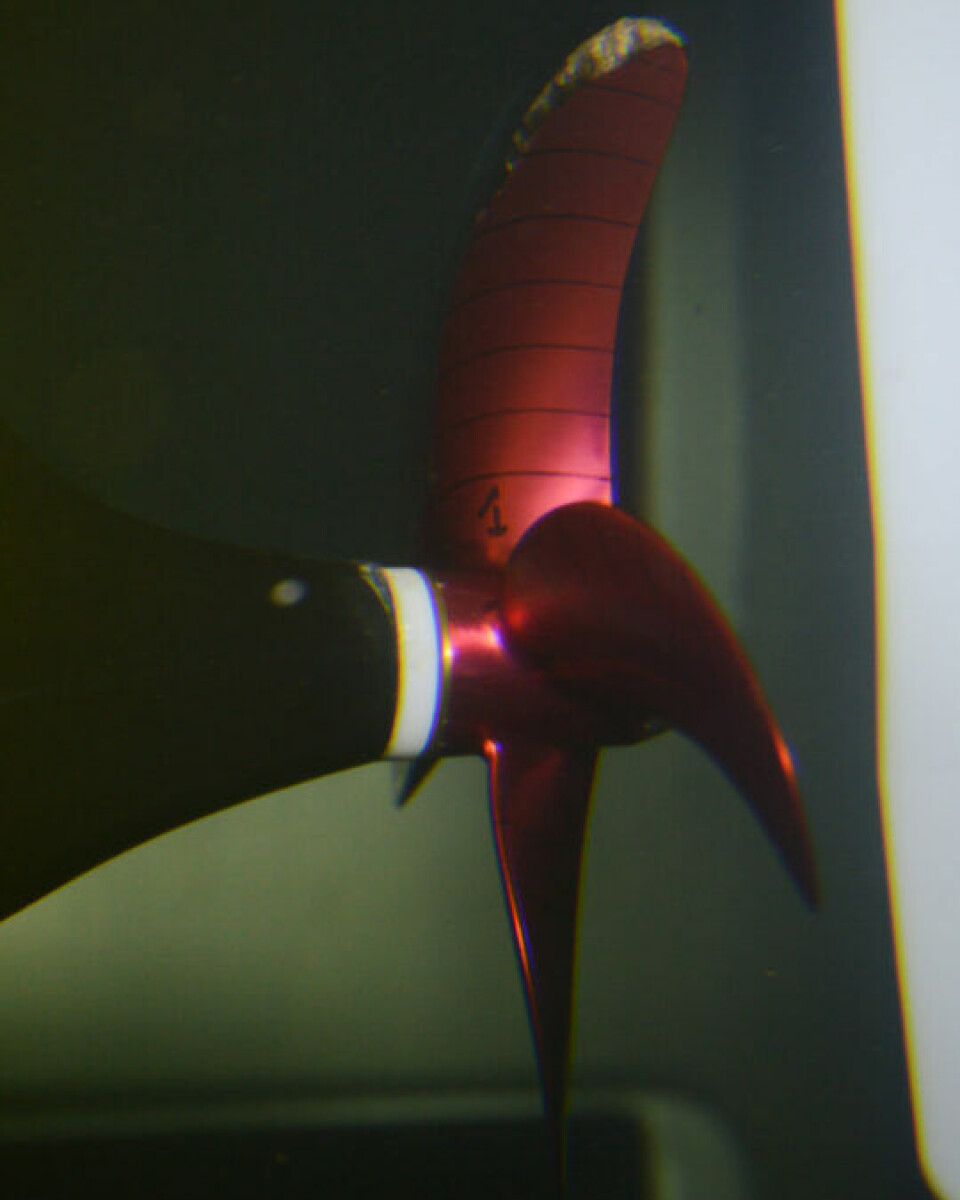

“The propeller has a diameter of 10.8 metres. A three-story house is typically around nine to ten metres tall, so we’re talking about massive dimensions,” says Hamstad.

The researchers will also determine how much fuel the vessel needs through propulsion tests. Seakeeping tests are used to see how the ship moves and behaves at sea, under all kinds of weather conditions.

Looking at global wave statistics

Hamstad and his colleagues use a special map to determine wave direction and size. All the world’s oceans are divided into regions, and using the map, the researchers can find wave statistics for each area.

Based on this information, Hamstad can decide what wave heights the vessel should be subjected to during the tests.

The propeller and hull are tested in the cavitation tunnel. Cavitation is when the pressure on the propeller blade becomes so low that the water starts to boil or form bubbles. This damages the propeller.

“We have just under 2,000 stock propellers that we use in our experiments,” he says.

An international collaboration

The client, China Ship Design & Research Center Co. (CSDC), is one of the world’s largest ship design firms.

“SINTEF’s tests help us optimise our designs, ensuring safety, efficiency, and environmental compliance in our large vessel projects,” says Zhang Jinliang from the R&D department in CSDC.

The shipowner in Brazil now plans to build 10 ships like this. When the tests in Norway are done, the building process in China starts.

More content from SINTEF:

-

It's tough to be a nurse: Many also have to clean and do kitchen work

-

300 meals can be saved from this kitchen – every month

-

Saving seagrass and French oysters: New solutions give new life to Europe's coastal areas

-

What does ultra-processed food do to our gut flora?

-

This new device can make it cheaper to heat your home

-

Propellers that rotate in opposite directions can be good news for large ships