THIS ARTICLE/PRESS RELEASE IS PAID FOR AND PRESENTED BY SINTEF - read more

Seeks to capture 1 million tons of CO2 from the air per year

In collaboration with SINTEF, the industrial company Removr aims to become a world leader in direct CO2 capture from air.

We are releasing more and more CO2 into the atmosphere. Now we need to find technologies that can remove what has already been released – in addition to dramatically reducing the emissions. Removing existing CO2 from the atmosphere, known as historical CO2, will be a necessary solution if we are to achieve the climate goals, according to the UN Intergovernmental Panel on Climate Change.

If we succeed in creating a large industry based on CO2 capture, also called 'climate-positive technology', Norway can take a leading role.

“The value chain will be able to create new jobs, in addition to having major ripple effects in the districts where the facilities are established. We need to put in place the framework so we can develop this in a way that safeguards the sustainability goals in the UN,” Einar Tyssen, CEO of the industrial company Removr, says.

In collaboration with SINTEF as a research partner and the technology partner GreenCap Solutions, Removr is now putting in place a large-scale CO2 capture facility from air.

The solution in development is called Direct Air Capture (DAC) technology. According to the partners, Norway can take on a world-leading role within DAC by using renewable energy sources in combination with cost-effective capture technology.

Pilot in Iceland

Removr is already developing a pilot for DAC technology in Iceland.

Today, Iceland leads the way on CO2 capture from air. The country uses its naturally good conditions related to clean energy and storage in the basalt formations in the subsurface.

“In Iceland, we get access to both renewable power and storage that makes it possible to demonstrate the technology quickly. Only in Iceland can a full value chain be realised at the moment. This means that the country has become the world’s display window for carbon capture from air,” says Tyssen.

Zeolite as core technology

The core of the DAC technology is the material zeolite. Zeolites are porous and attract carbon dioxide from gas mixtures in the small pores of the material. In this way, the CO2 molecules are separated out of the air.

SINTEF has many years of experience with zeolites and the development of technologies that use microporous absorbents.

“Zeolites are found naturally as minerals, but for use in the industry they are most often produced synthetically,” Jasmina Hafizovic Cavka, research leader at SINTEF, says.

“The material is used in several separation processes, such as purification of water and separation of oxygen from air for use in hospitals. In the context of DAC technology, the extensive use of zeolites is positive in that the materials are not toxic and that they are commercially available on a large scale, which is crucial for the implementation of DAC technology” Cavka continues.

Vacuuming the air

With DAC, CO2 is 'vacuumed' directly from the atmosphere, so that the CO2 concentration and greenhouse effect is reduced. However, the CO2 concentration in the air is only around 0.04 per cent. This is about 300 times lower than what comes from the exhaust gas in a coal-fired power station.

In other words, the concentration of CO2 must be increased to more than 95 per cent. In addition, the greenhouse gas must be stored under ground. This will be done by mixing the CO2 with water and then storing it in the geological layer under the island: basal formations. After 1-2 years, the mixture will be mineralised, that is converted into stone.

“We build capture facilities that blow large amounts of dried and refrigerated air through a microporous material that captures the CO2 molecule in the pores. However, since the CO2 concentration in the air is low, the plants must be large before they will have a significant effect. Our goal is to reach a capacity of 1 million tons of CO2 per year," Einar Tyssen says.

Large-scale benefits crucial for the economy

The fact that DAC-plants must process large amounts of air, requires a lot of clean energy and large facilities. The biggest challenge in today’s DAC technologies is therefore high investment and operating costs.

“To reduce the energy demand and footprint, more research is needed, both on the CO2 capture materials and optimisation of the capture process itself. In addition, standardised life cycle analyses and techno-economic analyses are crucial,” Jasmina Cavka says.

Modelling of full-scale rigs

The research team will now start modelling the capture process that will form the basis for the design of a full-scale capture facility. More knowledge about dimensions, the amount of zeolite and the energy consumption is particularly needed.

References:

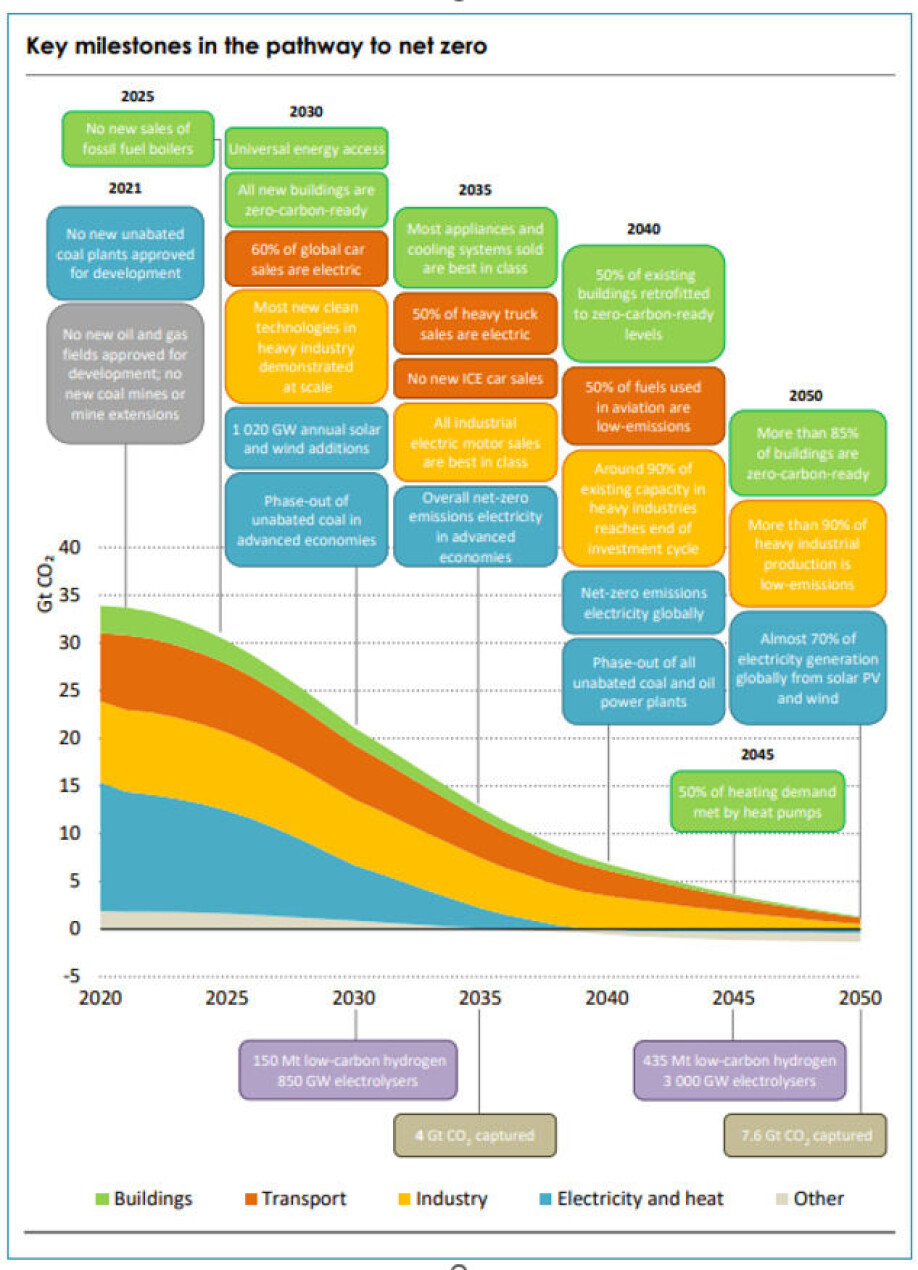

Net Zero by 2050, A Roadmap for the Global Energy Sector, International Energy Agency, 2021.

See more content from SINTEF:

-

Saving seagrass and French oysters: New solutions give new life to Europe's coastal areas

-

What does ultra-processed food do to our gut flora?

-

This new device can make it cheaper to heat your home

-

Propellers that rotate in opposite directions can be good news for large ships

-

How Svalbard is becoming a living lab for marine restoration

-

New study: Even brand-new apartments in cities can have poor indoor air quality