This article was produced and financed by Nofima The Norwegian Institute of Food, Fisheries and Aquaculture Research - read more

Using light to ascertain the quality of fish has the potential to revolutionize the fishing industry

This new technology will soon be commercially available.

“For the first time ever, we are able to provide an objective measurement of good quality already when whitefish is delivered on shore and to the processing plants,” says Karsten Heia, Senior Researcher at Nofima.

By using high throughput light and imaging technologies, the fish can also be automatically sorted according to species upon delivery.

“There is extreme technology and physics behind this method which has been produced and tested to further develop the Norwegian fisheries industry. The technology could be compared to techniques used in medical scanning of the human body, however here it is being developed to meet with processing speed used in the fish industry. It is very exciting,” says Heidi Nilsen, Head of Research in the Seafood Industry Department at Nofima.

Scanning for blood stains and blood clots

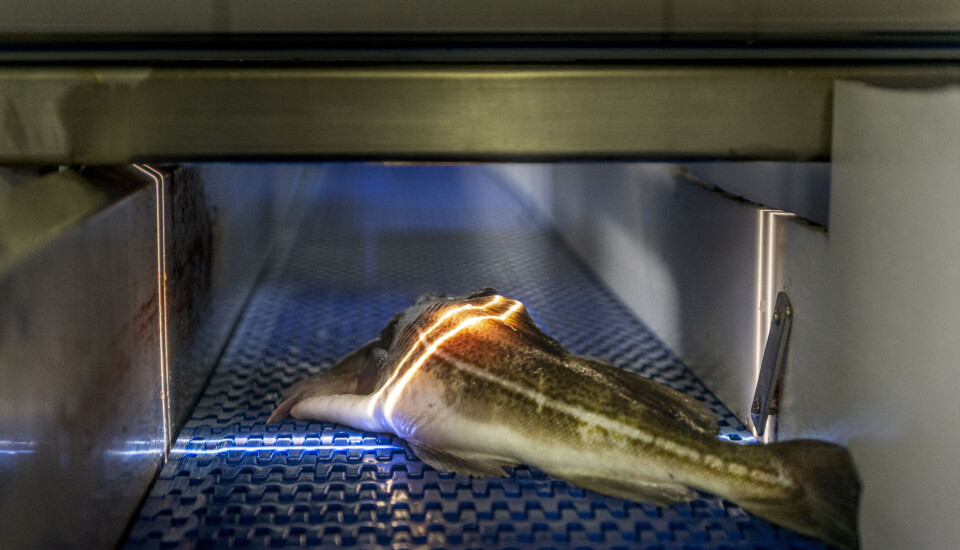

The technology enables quality measurement using sensor technology based on light, which in technical terms is referred to as hyperspectral imaging.

A good quality exsanguinated (bled out) fish, has white and delicate flesh. A fish that has not been bled out or has been damaged during catch will have blood stains and blood clots in the muscle. The fish are illuminated on the production line and blood content in the fish muscle is assessed from light signals reflected to the sensor. The entire process happens, literally, at the speed of light. The machine is able to measure and analyse fish on conveyor belts with a speed of two metres per second. Hence, upon receival from the vessels, the fish can then be sorted directly into different quality classes based on the blood content.

The technology enabling this quality measurement is planned to be commercially available by autumn 2020, and from then on applicable on an industrial scale.

“The machine has been tested. We see that the technology works. We are able to analyse the data continuously as soon as it is generated, and we are in the process of integrating the machine with the gradient – the sorting machine – in the production line. We are ready to put the machine into production,” affirms Karsten Heia.

These automatic measurements of blood in whitefish have the potential to shift quality sorting – and profits – to new heights.

World-leading

The whitefish industry in Norway has long sought automated quality sorting of whole fish based on blood content. Nofima has researched this crucial technology since the early 2000s.

Karsten Heia has worked with the technology company Norsk Elektro Optikk (NEO) for 16 years to develop a hyperspectral camera for food use.

Norsk Elektro Optikk (NEO) built its first hyperspectral camera in 2003. That same year, Nofima initiated a collaboration to develop a camera for use on fish.

“We appreciated this greatly, and it was the start of the very exciting developments we have had. Today, we are world-leading in the high-end market,” says Trond Løke, Manager of HySpex, the hyperspectral department in NEO.

By 2018, the development of the camera and machine intended for quality measurement of fish had progressed to a level applicable for industrial testing.

“Being a part of utilizing this technology in an industrial initiative in Norway is something we are proud of. Norway has a strong global position when it comes to research into food and fish, not to mention the development of hyperspectral cameras. And we are very proud that NEO and Nofima have now developed something that works in the industry,” says Løke.

Another person with reason to be proud is Nofima researcher Stein-Kato Lindberg, who worked on the data analysis, software testing and machinery in Båtsfjord, where the industrial trials were carried out.

“It’s very varied, informative and interesting work. It’s also very rewarding to work with something that is of great interest to the industry, and that eventually will be offered on the market,” says Lindberg.

Can deliver precisely what is offered

“The technique implies several advantages to the seafood industry. When you are able to evaluate the quality of the raw material upon delivery, you will know early on in the production which product mix you are dealing with. This means that the sales department can immediately start the job of selling the catch. Today they do not know what quality they can offer, and it is based on their discretion, whereas after quality measurement they will know that they can deliver precisely what is offered,” says Karsten Heia.

According to the researcher another advantage of this kind of measurement is that before production commences you know how much is available for high-quality products, such as loins and fillets, how much can be sent in bulk to be used in, for example, fish mince, or what is best suited for production of salted fish.

“After measurement, producers who only stock fillet products will know early on how much raw material of top quality they have at their disposal, they know how much raw material needs to be trimmed, and they know how much is of such a quality that it will not be profitable to spend resources on trimming,” says Heia.

And adds:

“As sorting can be done on land and thereby increase profits, one can perhaps reward the vessels that deliver high quality catches.”

The entire value chain will benefit from this

The fishing fleet, which can install the system in its production line, will be able to gain much greater control of its own products.

“The sea fishing fleet delivers a lot of frozen raw material which may not enter the market for four or five months. If they receive a complaint about the quality, they may not have adequate knowledge about the possible causes, and thus little room to argue. By measuring and documenting the quality of all fish brought on board, they will be able to sort according to quality and avoid surprises and price reductions later on,” says Heia.

And since all the data from the measurements are collected and systematized, production facilities and the trawler fleet can learn more about the causes of quality variations. This means the entire value chain will benefit from this.

“The challenge has been to make measurements and analysis simple enough so that it will be appropriately priced to be able to mass produce without compromising on system quality. This is what we have now achieved,” says Heia.