THIS CONTENT IS BROUGHT TO YOU BY the Norwegian University of Life Sciences (NMBU) - read more

Can coffee grounds and eggshells be turned into fuel?

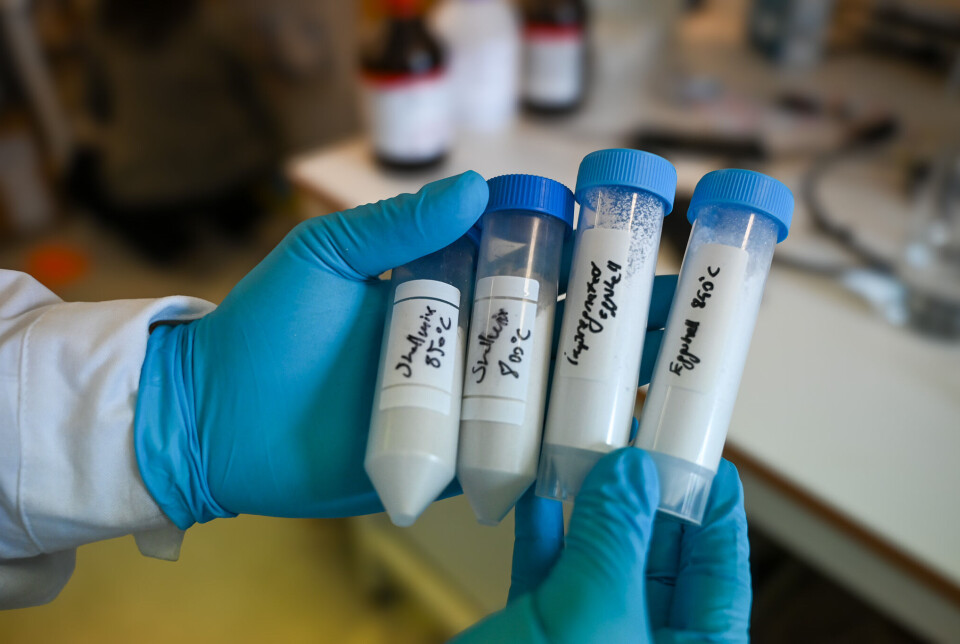

Researchers are investigating whether they can use coffee grounds and shells from mussels, shrimp, or eggs to produce biodiesel in the most sustainable way possible.

A large part of Europe's emissions comes from vehicles that use petroleum-based fuels. If we are to reach the EU's ambitious climate goals of reducing emissions by 55 per cent by 2030, we need environmentally friendly fuels.

At the Norwegian University of Life Sciences (NMBU), researchers are working on producing biodiesel from waste. The goal is to use as many reusable materials as possible so that the entire production process becomes more sustainable.

The main material is coffee grounds.

Coffee grounds into biofuel

“Norway is among the countries in the world where we drink the most cups of coffee per capita. That results in a lot of coffee grounds,” says Jorge Marchetti, professor of physics at NMBU.

He was wondering whether coffee grounds could be used for something else before they end up in the trash.

“How many times can we use coffee grounds before they end up in the trash or compost? We try to extract as much as we can from the resources before we say they're useless,” he says.

After we have brewed coffee and extracted what we want to use, such as the coffee flavour and caffeine, there are still a lot of nutrients left.

Coffee grounds are organic material. They can be used for many different things. You can use them as fertiliser, to improve soil , or as compost in the garden.

Or something more advanced: To produce biodiesel. That's what the researchers in Marchetti's project are trying to use it for.

Food waste becomes new products

Jorge Marchetti leads the research project called UNPRECEDENTED. Here, researchers from Norway, Portugal, and Argentina collaborate.

It is a complex chemical process they are conducting. It consists of several elements.

For the oil from coffee grounds to become biodiesel, it must be combined with various chemicals and alcohol. To make the chemical process happen, researchers also need a catalyst.

“The catalyst is a component that you need for the process to happen, which does not intervene in the process itself. For example, if you want to deep-fry an egg, you need oil. You don't eat the oil – you eat the egg. But without the oil, the egg will not be deep-fried,” explains Marchetti.

In this project, the catalyst is also from waste materials. Researchers use calcium oxide, which can be found in shells from eggs, mussels, and shrimp.

To produce fuel, you also need alcohol. The alcohol they use is renewable ethanol from sugar cane.

The goal is to use bio-based and renewable solutions for every step of the process.

“We look at all the materials involved and how we can make the process more environmentally friendly. We want to make it as circular as possible in the sense that we use the end product of a product that would normally have been discarded,” says Marchetti.

New method for biodiesel production

The project aims to develop a completely new method for producing biodiesel from waste oil.

For this, they use a combination of experimental data and theoretical modeling called Density Functional Theory (DFT). The researchers use the model to understand what happens between the chemicals at the atomic level.

“When we use DFT, we can create a model that shows how the atoms in a substance interact with each other. The model gives us an idea of which chemical reactions can occur and how we can expect the substance to behave. This means we don't have to experiment as much in the laboratory,” says Marchetti.

The DFT method gives researchers input on what they can expect in the laboratory. They get a hint about the most promising experiments – or which experiments they should not do.

When researchers can conduct fewer experiments, it saves time, money, and resources.

What makes this research completely new is the combination of all the elements together.

“The elements we use have been tested before, but not together. We combine them to create a completely new production process for biodiesel. It's a combination of three or four small innovations together that makes the whole process new,” says Marchetti.

The research team is now halfway through the project period, and the results are promising. The models are accurate, and the method works.

For Marchetti, however, the most important thing is that the knowledge and methodology they are building provide a solid framework that can be used by others.

“Of course, we aim to produce biodiesel from coffee grounds. But if we don't succeed, we'll still have laid the foundation for a new methodology that can be used in many other areas,” he says.

He highlights fields like medicine or materials science.

“This is a new approach that should serve not only our field, but any field,” says Marchetti.

More content from NMBU:

-

Shopping centres contribute to better health and quality of life

-

We're eating more cashew nuts – and the consequences are serious

-

Do young people with immigrant parents have better health?

-

Who’s picking your strawberries this summer?

-

Rising housing costs fuel inequality in Norway

-

Researchers warn: Climate change in African mountains has a greater impact than previously thought