THIS ARTICLE/PRESS RELEASE IS PAID FOR AND PRESENTED BY SINTEF - read more

Recycled snuff boxes can become new products

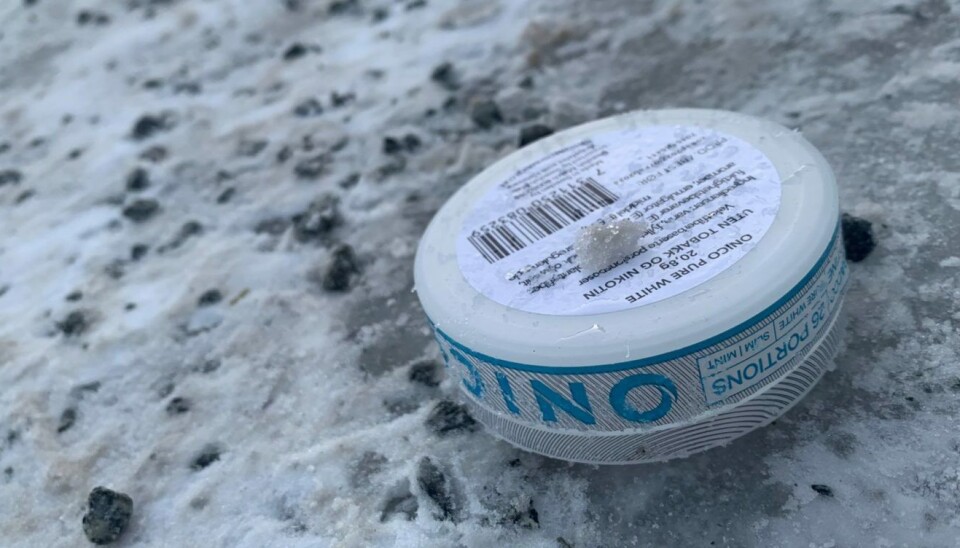

Empty snuff boxes litter many streets and parks in Norway.

The plastic used to make snuff boxes is polypropylene, also known as PP plastic, which is one of the most common plastics used in consumer products.

This makes snuff boxes relatively easy to recycle to make new products.

Researchers at SINTEF are now looking into opportunities for giving these little boxes a more sustainable, and perhaps circular, life cycle.

The aim of the new project is to prevent empty plastic snuff boxes from being treated as rubbish and ending up littering our parks and polluting the oceans.

How can we recycle the boxes?

Researchers have conducted a number of laboratory experiments involving first melting and then testing the strength of the recycled plastic. They have investigated the types of new product that the plastic can be made into, and assessed the level of purity required for it to be suitable for recycling.

The less paper the plastic boxes are covered with, the purer the recycled plastic will be, making it available for a wider variety of new products.

Plastic from the cleanest recycled boxes could in fact replace the new plastic used for the majority of products today.

Boxes that are contaminated with residual traces of paper could be suitable as raw materials for items such as wedges or reinforcement spacers used in the construction industry.

What about quality?

Not surprisingly, the quality of the recycled plastic was somewhat poorer than that in a new snuff box, but the difference was so small that it was hardly noticeable provided that uncontaminated boxes were used as the raw material.

The most contaminated boxes resulted in plastic that had other properties. For example, it was less easily moulded and thus not suitable for products that required thin plastic, such as packaging.

“However, there are many applications for the these coarser plastics. They can be used in products such as moulded furniture or other large items,” Ole Vidar Lyngstad says.

He is a research scientist at SINTEF.

“It has to be up to the manufacturer to select for quality on the basis of what is regarded as adequate for the product in question,” he says.

Collection and recycling is the most eco-friendly approach

Adequate quality is the most important factor we must consider when assessing the profitability of plastic recycling. If the quality is significantly diminished, recycling will simply not be profitable.

According to researchers, if snuff box plastic is of high quality, it can be recycled many times if stabilisers are added before the quality becomes significantly degraded.

Nevertheless, by far the most eco-friendly thing we can do is to establish a deposit system and recycle used snuff boxes to make new ones.

However, this is not permitted in the EU, where food safety guidelines focus in particular on the thermoplastic PET (polyethylene terephthalate), which is the standard in drinks bottles.

According to Lyngstad, the guidelines cannot be transferred to apply to snuff boxes.

Collected snuff boxes may represent a major source of a uniform plastic raw material that has high value in the recycling market because it is easy to utilise in products that demand high quality.

Paper labels are the big problem

However, high quality demands that the plastic is free of paper contamination.

Removing the paper is a relatively resource-demanding process because it is difficult to wash away. For this reason, manufacturers Swedish Match are looking into testing alternative packaging that uses PP plastic instead of paper. This appears to be the best option if the aim is to ensure the profitable recycling of plastic snuff boxes.

With recycling in mind, removing the paper from all plastic packaging would be a good start. According to researchers, it will eliminate a major contamination problem from the plastic cycle.

This is something that the entire packaging industry will benefit from knowing.

See more content from SINTEF:

-

300 meals can be saved from this kitchen – every month

-

Saving seagrass and French oysters: New solutions give new life to Europe's coastal areas

-

What does ultra-processed food do to our gut flora?

-

This new device can make it cheaper to heat your home

-

Propellers that rotate in opposite directions can be good news for large ships

-

How Svalbard is becoming a living lab for marine restoration