THIS ARTICLE/PRESS RELEASE IS PAID FOR AND PRESENTED BY NTNU Norwegian University of Science and Technology - read more

Nature’s colours can replace toxic pigments

Dye pigments are often toxic, so researchers around the world have long been looking for effective ways to make non-toxic, recyclable and sustainable colours instead. The answer lies in nanotechnology and nature’s own methods.

Dyes that humans make often contain substances that are harmful to the environment. But it doesn’t have to be that way anymore.

“We’re mimicking normal colour mechanisms in nature,” says Jon Otto Fossum, a professor in NTNU’s Department of Physics.

He and others from the research group are collaborating with a research team at the University of Bayreuth in Germany. They have discovered a practical and inexpensive method for producing colours that are sustainable and non-toxic. These colours will be both recyclable and sustainable as well.

The researchers are using nanotechnology, where they manipulate materials all the way down to the atomic level.

Their work was first presented during postdoctoral fellow Paulo Michels-Brito’s PhD dissertation. The results have now been published in Science Advances.

Colours in nature are different

When your house or car has been given a colour, it is usually paint, stain or varnish that has been applied. The colour of the house or car depends entirely on the material of the paint or varnish. The colour we see is the part of the light spectrum that the material does not absorb.

But nature’s way of making colours is often completely different.

“Birds, fish, insects, some plants and berries, soap bubbles, the rainbow and so on have colours that are based on a partial reflection of light waves,” says Fossum.

What we see is light that is reflected in nanothin structures in the material. The light reflected in the different layers is amplified through what’s called ‘constructive interference.’ This creates what we see as colours.

To imitate this way of making colours, the clever heads at the Department of Physics have used nanothin layers from a seemingly humble material.

Clay.

Nanothin sheets of clay

“Most people don’t think of clay as transparent. But if we isolate nanothin sheets of clay or graphene, for example, they become almost completely transparent. They don’t reflect light and are colourless,” says Fossum.

But by combining two such transparent clay sheets and putting an additional substance in between, it is possible to bring out colours.

“We can make clay nanosheets less transparent by making and using a double nanothin layer with an element between them. In this example, we used the element caesium, but other substances can also be used,” says Fossum.

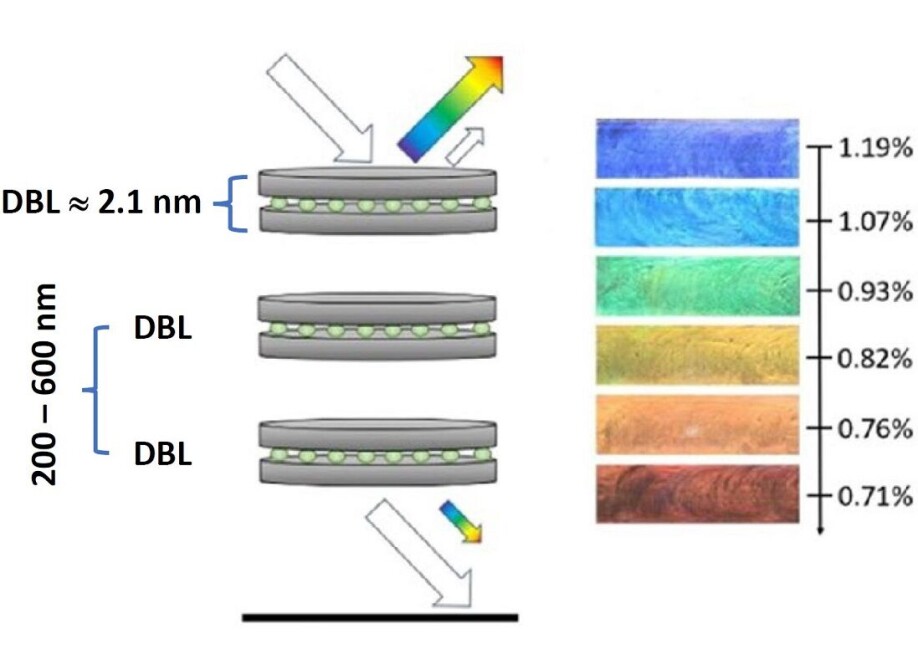

The researchers call the double nanothin clay layers DBL (‘Double Layers’). Double clay layers are still partially transparent, but reflect some light that produces colour.

Distance between layers determines colour

“The mechanism we work with is called ‘structural colour’ because it’s the nanostructure, and not the specific material, that gives rise to the colours,” says Fossum. “That’s why structural colours are also often called ‘physical colours,’ whereas traditional pigments are often called ‘chemical colours.’

The material has properties at the nano level that make it possible to reflect light from different depths in the structure. This can in turn result in different colours because the combined light from the different layers amplify each other in the same way as we see in soap bubbles or rainbows.

“The distance between the double clay layers is what produces the colour we see. We can control the distance by means of the clay concentration or salt content in the material, such as water, that the clay is suspended in,” Fossum explains.

In this example, the water is the ‘matrix’ of the clay layers. This matrix has to be absolutely transparent for the double clay layers to reflect and give rise to the colours.

Complex materials

“From a basic science perspective, this system is a textbook example of what we mean by complexity, including self-assembly of complex materials,” says Fossum.

The Nobel Prize in Physics for 2021 was given to scientists who research complex systems.

“A complex system is made up of several components that together contribute to the desired functionality, in this case colours,” says Fossum.

The colours themselves come from the clay layers, while the matrix keeps everything in place. The result is more than just the sum of the components, because they’re self-assembled in a special way at the nanoscale, Fossum says.

Environmentally friendly instead of toxic

All this could bring about a lot of changes and provide a far more environmentally friendly way of colouring many products in lots of areas.

“Chemical pigments are often toxic, whereas physical colours can be produced from anything that is almost transparent,” says Fossum.

This applies to materials that are harmless and sustainable, like clay suspended in water or in transparent recyclable polymers or biopolymers. The latter are chemical compounds that are made up of chain-like molecules.

“The physical colour mechanism isn’t yet used very widely by industry. The chemical mechanism dominates.

The reason is that we haven’t yet found a way to fabricate structural colours that is fast, efficient and practical for industry, says Fossum.

But that hurdle won’t last forever .

“Our findings open up a much more extensive use of nature’s way of making colours, instead of the toxic and unsustainable way we humans have been doing,” says Fossum.

That’s why this research is important, not only for producing paints or varnishes but also for use in cosmetics, food packaging and in several other areas.

The new method is now being patented in collaboration with NTNU Technology Transfer (TTO).

You can read more about this research and much more on the webpage for the Soft and Complex Matter Lab, where Fossum and Michels-Brito work.

Reference:

Paulo H. Michels-Brito et.al.: Bright, non-iridescent structural coloration from clay mineral nanosheet suspensions. Science Advances, 2022.

See more content from NTNU:

-

Why is nothing being done about the destruction of nature?“We hand over the data, but then it stops there"

-

Researchers now know more about why quick clay is so unstable

-

Many mothers do not show up for postnatal check-ups

-

This woman's grave from the Viking Age excites archaeologists

-

The EU recommended a new method for making smoked salmon. But what did Norwegians think about this?

-

Ragnhild is the first to receive new cancer treatment: "I hope I can live a little longer"