THIS CONTENT IS BROUGHT TO YOU BY SINTEF - read more

Researchers are creating a self-repairing and environmentally friendly electric car battery

The goal is to eliminate both charging anxiety and environmental concerns. Researchers have now created the ‘recipe’ to do it.

Imagine that you are travelling down one of Europe’s many superhighways in your new electric car. You’re moving fast, but charging stations are few and far between. A flicker of range anxiety kicks in – until you remember that your car is equipped with a brand new battery designed for long distances and minimal charging stops. And when you do need to recharge, it takes significantly less time.

With this in mind – and the certainty that the new batteries are also more environmentally friendly – you relax into your seat and drive on with confidence.

More power in every ‘drop’

The EU is investing in the production of new electric vehicle (EV) batteries that are more sustainable, cheaper, and efficient. The goal is to encourage as many people as possible to drive with sustainability in mind.

Nils Peter Wagner is a senior research scientist at SINTEF and coordinator of the EU IntelLiGent project. He says that researchers have experimented with both advanced materials and components to improve the batteries.

“In many ways, you could say we’ve created a ‘recipe’ for future battery technology by choosing some of the best, cheapest, and least environmentally harmful raw materials," he says. We have investigated every last detail of the battery cells,” says Wagner.

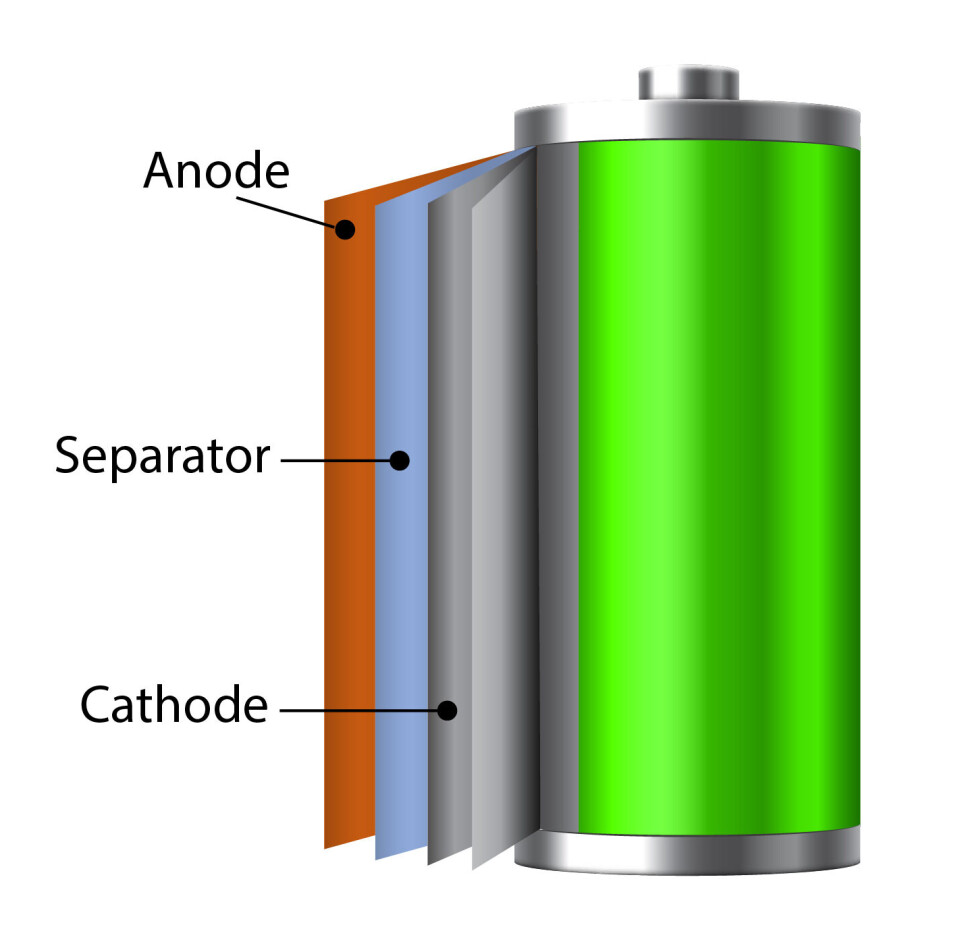

Building a better battery

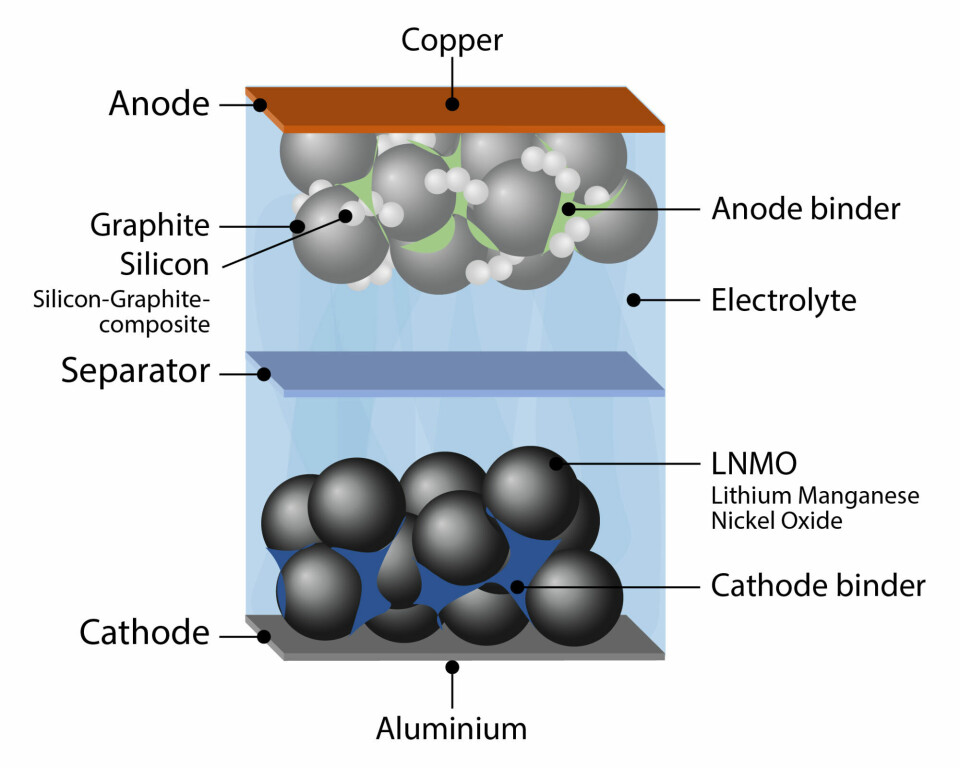

Think of the battery as a sandwich: on top is the cathode, which in this new design is made from lithium-nickel-manganese oxide (LNMO). Unlike traditional battery materials, LNMO is cobalt-free and contains less lithium and nickel, reducing environmental impact.

“The LNMO cathode material provides high average voltage, without failing. It also has high energy density, which means that it can create more energy in a smaller volume, so that the battery has a longer range,” says Wagner.

However, one challenge has been that the material has had some 'growing pains' that resulted in a shorter lifespan. Researchers have now developed a new generation of LNMO cathodes that provide better performance and capacity for the batteries.

At the bottom of the battery is the anode, made from a composite of silicon and graphite. Silicon can absorb many more lithium ions, which provides more energy, while graphite provides strength and stability, so that the battery lasts longer.

Both silicon and graphite are critical raw materials. IntelLiGent’s silicon-graphite composite batteries are produced by Vianode in Norway, which can produce materials with both lower emissions and resource consumption.

Follow-up problem solved

“These energy-efficient, high-capacity anodes play a crucial role in improving battery performance. However, silicon anodes swell significantly during charging and discharging, and this can cause the material to break down," says Wagner.

He explains that they have solved that problem by exploiting the stability of graphite, so that the batteries have the best possible durability and lifespan.

The research team is also developing a ‘secret sauce’: a special electrolyte that protects both the anode and cathode. This makes them more stable and increases the lifespan.

Wagner explains that they recently developed and tested this electrolyte in a first-generation prototype.

“Now we’ve put the spotlight on the second generation of prototype cells, which will provide higher energy density and use even larger cells. This will in turn give the batteries even better performance and efficiency,” he says.

Superglue repairs minor damage along the way

Researchers have also worked on the battery's internal structure, including how the electrodes are constructed and how the battery is assembled, to enhance energy density and charging capacity.

“One effect of higher energy density is that the battery can get too hot. We need to ensure that the structure does not allow heat to build up inside the battery,” says Wagner.

In order to hold the ‘sandwich’ together, the research team uses special binders and separators. These parts are not passive helpers, but active components that can repair minor damage along the way.

While the binders help to maintain the electrode structure, the separators ensure that the electrodes are kept physically separated, thus preventing short circuits.

“The binders and separators allow the batteries to protect and repair themselves, which in turn helps to extend their lifespan,” says Wagner.

A virtual test track

To better understand the behaviour of the battery cells, the researchers use advanced analysis methods and modelling. This provides useful answers on how the design can be improved.

Using these tools and methods, researchers can explore the possibilities, looking for the most environmentally friendly solutions, even testing the batteries in a digital world. By using a software tool developed at SINTEF, they can test how the batteries behave, saving time and ensuring that the technology works as expected.

From lab to market

IntelLiGent collaborates with key industry players across the value chain, from manufacturers to suppliers and end users, to create the best possible battery.

How do these innovations make their way to consumers?

The team has a clear roadmap to bring the technology to market, including scaling up electrode production, optimising production and testing processes, and developing a demo model to validate safety and performance.

Towards a greener future on the road

“We're assessing environmental, economic, and social consequences, and comparing the new technology with current solutions,” Wagner says.

According to the researchers, this EU project paves the way for a greener automotive future, with batteries that are more powerful, more efficient, and less harmful to the planet.

“These batteries will enable you to drive your electric car farther without charging and you’ll be able to charge it faster. As an individual, you’ll also be contributing to a smaller carbon footprint,” he says.

More content from SINTEF:

-

Saving seagrass and French oysters: New solutions give new life to Europe's coastal areas

-

What does ultra-processed food do to our gut flora?

-

This new device can make it cheaper to heat your home

-

Propellers that rotate in opposite directions can be good news for large ships

-

How Svalbard is becoming a living lab for marine restoration

-

New study: Even brand-new apartments in cities can have poor indoor air quality