THIS CONTENT IS BROUGHT TO YOU BY NTNU Norwegian University of Science and Technology - read more

This new construction solution will extract heat directly from the Earth

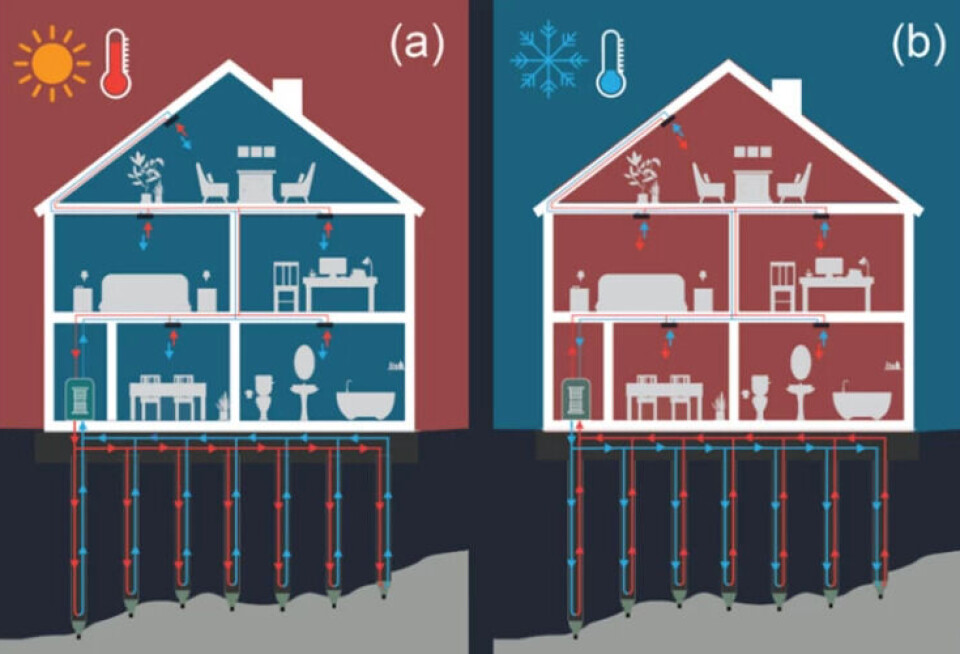

Geothermal heat can be extracted directly via the piles used to anchor buildings in the ground. This invention makes it easier and more affordable to use environmentally-friendly energy.

A new piling joint, which has now been patented by NTNU Technology Transfer AS, connects pre-fabricated concrete elements to achieve the desired length in a quick and safe manner.

The piles are anchored in bedrock and equipped to use geothermal heat directly to heat or cool buildings.

No need to bore separate wells

The new solution means that building owners who want to use geothermal heat no longer need to bore separate wells to obtain it, a process that is both costly and challenging.

So far, no one has been able to extract geothermal heat directly through the foundations of a building in an affordable and efficient manner.

Connections using the LEGO principle

The key to the DEP Joint (Driven Energy Piles) project is a square pile joint made from steel, which has been further developed by PhD candidate Habibollah Sadeghi at the Department of Civil and Environmental Engineering at NTNU.

The joint piece is equipped with two male and two female dowels that can quickly and easily be connected to one another. Two steel bolts are used to lock the joints together.

“It’s reminiscent of the way you build LEGO,” Sadeghi says. He has designed some new openings on the sides of the pile joints.

The openings allow for embedded tubes to be connected safely and efficiently without affecting the load-bearing capacity of the piles.

Heat with tremendous potential

After solar energy, geothermal heat is the largest available source of renewable energy.

As much as 99 per cent of the Earth has a temperature above 1,000 degrees Celsius.

Combined with heat pumps, underground structures can utilise the stable heat that is available almost right below our feet – even somewhere cold like Norway.

The opportunities are vast, and many people are working to develop the technology so that it is sufficiently efficient and safe.

First PhD in energy piles in Norway

Habibollah Sadeghi is the first person in Norway to earn a doctorate in energy piles. At the start of his studies, he consumed all the literature he was able to come across in the field.

He says that he soon realised the limitations and challenges associated with pre-cast piles. Only simple elements with relatively short lengths were available on the market. There were also no solutions available to join the concrete pile elements together.

Got the idea from the U-Bahn in Austria

Sadeghi got the idea for a solution from a course in Switzerland and an example from Austria.

There are more than 100 kilometres of recuperator tubes running through the walls, bushings, and cast concrete slabs on the underground line in Jenbach.

Each year, the project harvests 175 and 437 MWh for heating and cooling respectively from the surroundings of tunnels and underground stations.

“The system gave me the idea of linking the pile elements together in an equally efficient and safe manner,” the researcher says.

Steel to strengthen load-bearing capacity

The joint piece and the concrete element are fastened by welding steel reinforcements to the joint piece.

The piles are cast in a factory, and super-strong hoses or energy loops are embedded.

These are connected simultaneously with the piles when they are driven into the ground. The liquid, which is heated by geothermal heat, circulates through these loops.

Strict quality requirements

A significant advantage of DEP Joint is that the system is based on pre-fabricated concrete piles. They are produced in large quantities and are therefore subject to strict quality and safety requirements.

Another advantage is that it will be much easier to check the quality of what comes ready-made from the factory than to inspect piles cast in boreholes at the construction site.

Sadeghi and his academic supervisor, Professor Rao Martand Singh, have worked closely with NTNU Technology Transfer AS to further develop the concept.

“There are no similar solutions available on the market today,” Lodve Berre, a business developer at NTNU TTO, says.

The challenges of current wells

The wells that are bored to extract geothermal heating for newbuilds today are often 150-300 metres deep. The boreholes result in large quantities of excess soil that needs to be removed.

Ground conditions can also pose various challenges. The soil, for example, might be contaminated and require special treatment. Changes to water levels can also lead to unstable ground conditions, as well as settlement and subsidence damage.

“DEP Joint piles can easily be used without any issue in areas with contaminated soil and low water levels,” Berre explains.

More piles instead of deep holes

Since the elements need to be transported from the factory to the construction site, they cannot be longer than 12-15 metres. This is a disadvantage, as long energy loops are desirable because they can extract more heat.

DEP Joint solves this dilemma as follows:

“Instead of boring a 300-metre deep hole, we can install 12 energy piles down to the bedrock situated at a depth of 50-60 metres instead. This will allow us to extract almost the same amount of energy,” Sadeghi says.

Quick return on the extra costs

The energy piles are slightly more expensive and take a little longer to install, but this is recouped in less than a year, according to the researcher.

In Norway, 250,000 metres of concrete piles are driven into the ground each year. Virtually all large buildings are equipped with such foundations. This, combined with the fact that the world has never before had a greater need for clean and efficient energy, lies at the heart of DEP Joint’s business concept.

“If we can reduce the energy requirements for heating and cooling of newbuilds by two thirds, it would correspond to enormous amounts of power saved globally. It would also help with the load in the power grid,” Berre says.

Particularly effective in cold climates

Habibollah Sadeghi has published several studies in which he has compared performance, potential, and economics of different heat pump systems used in both Norway and Europe.

Many solutions exist, but systems that use geothermal energy stand out. Installation costs are higher but are quickly recouped in relation to the building's lifespan.

“In colder climates such as Norway, geothermal pumps are particularly efficient, as the temperature in the ground remains stable,” the researcher says.

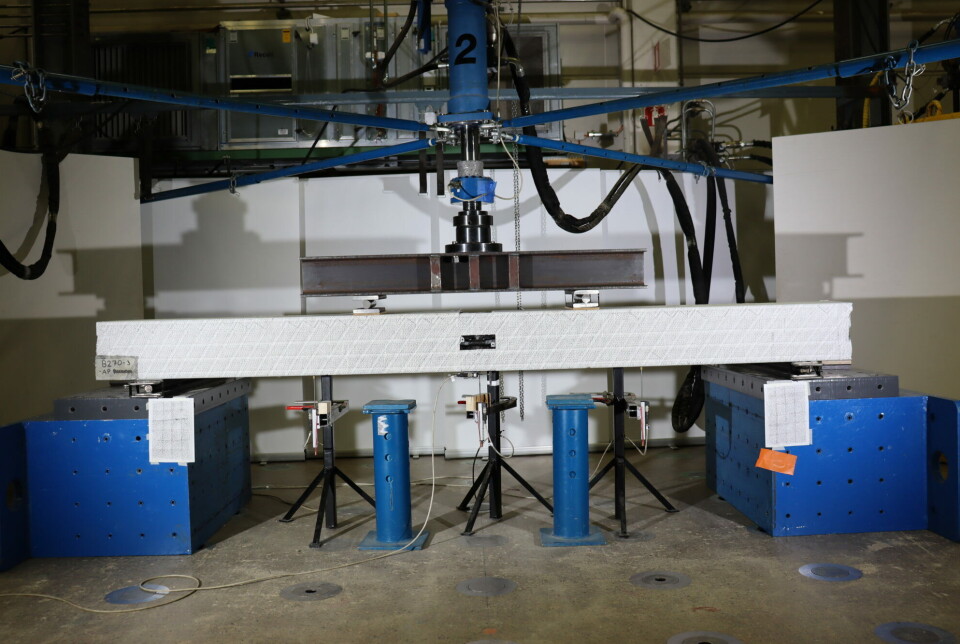

Tough tests in Finland

The initial prototypes were produced by the Finnish manufacturer Leimet Oy towards the end of 2022. Another partner, Sandnes & Jærbetong, have cast the connection in the piles.

In May 2023, the piles underwent very stringent European standard impact, pressure, and leakage tests at Leimet Oy. They were subsequently shipped to the Tampere University in Finland for deflection testing.

The piles are safe, strong and impervious

The tests showed that the joints escaped unharmed, and that both pipes and connections are impervious.

They also found that the piles have the same load-bearing capacity and strength as traditional, pre-cast concrete piles currently on the market.

This means that DEP Joint satisfies the requirements for CE marking. This means that the basic safety requirements have been met, and that the pile joint is ready for use in the construction industry.

Global market

Since all large buildings require foundations, the potential of the project is tremendous, the project stakeholders believe.

“And the market is global, as the solution is just as good for cooling as it is for heating,” Lodve Berre says.

This summer, a new energy pile will be cast in Stavanger. It will be 24 metres long and consist of one connection and two concrete elements.

The pile will eventually be installed near NTNU in Trondheim, where researchers will measure how much energy it is capable of retrieving. According to Habibollah Sadeghi, another goal is to install the piles under a standard new building.

References:

Sadeghi et al. Current status of heat pumps in Norway and analysis of their performance and payback time, Sustainable Energy Technologies and Assessments, vol. 54, 2022. DOI: 10.1016/j.seta.2022.102829

Sadeghi, H. & Singh, R.M. Driven precast concrete geothermal energy piles: Current state of knowledge, Building and Environment, vol. 228, 2023. DOI: 10.1016/j.buildenv.2022.109790

More content from NTNU:

-

Why is nothing being done about the destruction of nature?“We hand over the data, but then it stops there"

-

Researchers now know more about why quick clay is so unstable

-

Many mothers do not show up for postnatal check-ups

-

This woman's grave from the Viking Age excites archaeologists

-

The EU recommended a new method for making smoked salmon. But what did Norwegians think about this?

-

Ragnhild is the first to receive new cancer treatment: "I hope I can live a little longer"