THIS CONTENT IS BROUGHT TO YOU BY Nofima The Norwegian Institute of Food, Fisheries and Aquaculture Research - read more

Exactly how sweet is a tomato?

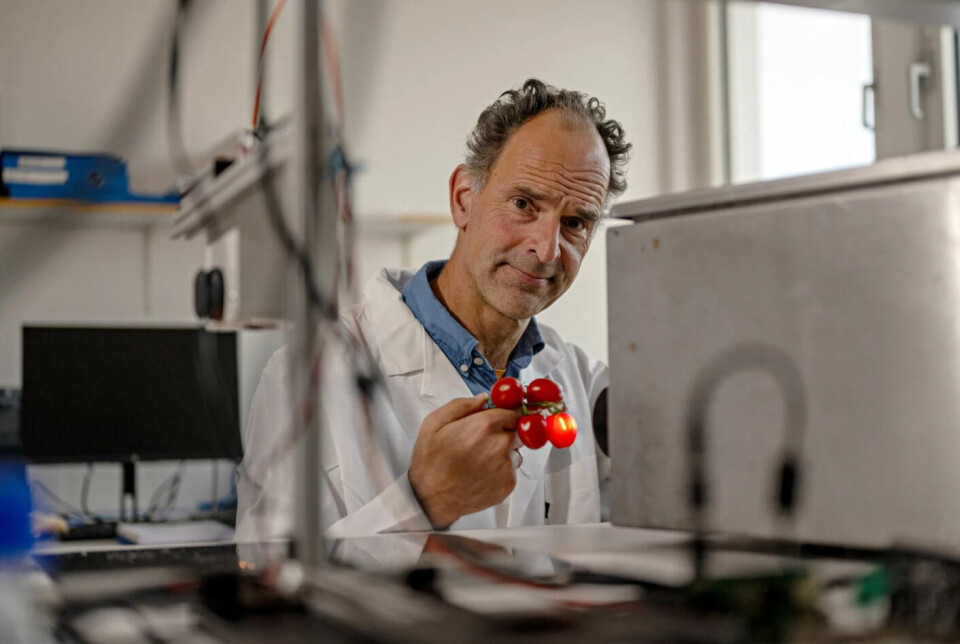

Norwegians love sweet tomatoes and are willing to pay a much higher price for them. Researchers have now developed a method that can measure just how sweet each individual tomato is.

The sweetness in tomatoes comes from the fruit sugar, and the concentration of sugar is measured based on a so-called Brix scale.

The most common way to measure Brix on fruit, berries, and vegetables is with an instrument called a refractometer. It measures the sugar concentration in the juice. This means that the juice must be squeezed out, and the fruit, berry, or vegetable is thus destroyed.

The researchers used an NIR sensor and developed a non-destructive measurement method for sugar concentration. This means that the tomatoes remain whole and undamaged.

NIR spectroscopy uses near-infrared light to measure the contents of a sample. The advantage of such a sensor is that it measures quickly and does not damage the sample. This allows the same sample to be measured multiple times.

Just sweet tomatoes, please

The measurements were made on sweet little Piccolo tomatoes grown by Wiig Gartneri.

They are now investigating whether rapid, non-destructive measurement methods could be the solution to ensuring that all Piccolo tomatoes are just as sweet as customers expect.

In the first instance, the tests are carried out at Nofima. The first 200 tomatoes where sent to Nofima in October 2023. They varied in ripeness – from dark red overripe to green very unripe.

“For us, it is crucial that every Piccolo tomato gives customers exactly the taste experience they expect. At the same time, we are dealing with living plants, and we have suspected that the sugar content can vary, even for tomatoes that sit on the same cluster and have the same red colour,” says Frode Ringsevjen, production manager at Wiig Gartneri.

Good calibrations require tomatoes with varying sugar content

The first 200 tomatoes were tested while lying still in their own plastic bowl.

To ensure that the measurements of the sugar concentration are correct and accurate for each individual tomato, the researchers have made numerous adjustments and adaptations to both the measurement methods and the instrument.

“The purpose of these first tests was to investigate whether we can get good measurements of the sugar concentration inside the tomato without touching it. Researchers at SINTEF have developed a NIR sensor that can measure them at a distance of eight centimetres. This was what we used in the tests. The results were very uplifting. We could measure sugar concentration with good accuracy,” says senior researcher Jens Petter Wold. He has led the study.

Among the tomatoes, there were green, yellow, orange, red, and dark red ones.

The large range in maturity is necessary when researchers are to test the measurement methods they develop. It is also necessary to ensure that the sensor measures the real sugar concentration and is not affected by the colours.

There turned out to be large variations in sugar content even among tomatoes that were the same shade of red.

Thoroughness is a keyword in the work of developing solid measurement methods. Frode Ringsevjen has sent an additional 100 tomatoes to Nofima.

This time, all the tomatoes were in the spectrum from orange to red. The researchers again tested whether the measurement methods were reliable. They then used the measurement results to place the tomatoes in eight different sweetness categories.

Correspondence between technology and human senses

In addition to the sensor measurements, the researchers made further quality checks. This time, against the senses.

Nofima’s professional sensory panel, consisting of 10 trained sensory assessors, tested tomatoes in the different sweetness categories and classified them based on flavour and odours.

“We were positively surprised by the correspondence between the classifications from the sensor measurements and from the sensory assessors. The differences were really tiny,” says Wold.

Measurements on the packaging line are the next step

The positive results from the first tests create optimism.

The researchers are now investigating how temperature can affect the measurements. They will also look at how the fruit sugar is distributed in the tomatoes. This is to better understand what they are measuring.

The next step will be to develop measurement methods that can also measure the sugar content in the tomatoes in motion, i.e., while they are moving, for example, on a packaging line and are still attached together in clusters.

A very useful tool

“High quality and great flavours are crucial for customers to choose our Piccolo tomatoes. We therefore already carry out thorough internal quality controls. A measuring instrument that can effectively weed out tomatoes with lower quality and less sweet taste will further strengthen this work. It will be a good tool to ensure that our loyal customers get the quality and taste they expect, without individual tomatoes spoiling,” Frode Ringsevjen points out.

The production manager hopes for a measuring instrument that can be used both as a handheld device to make quality checks in greenhouses, and mounted on a robot on the conveyor belt in the packaging plant.

———

Read the Norwegian version of this article on forskning.no

This content is paid for and presented by Nofima The Norwegian Institute of Food, Fisheries and Aquaculture Research

This content is created by Nofima's communication staff, who use this platform to communicate science and share results from research with the public. Nofima is one of more than 80 owners of ScienceNorway.no. Read more here.

More content from Nofima:

-

Red algae grown in wastewater from fish-farming facilities could become sustainable salmon feed

-

Pumpkins are good for more than just Halloween decorations

-

This is how temperature affects a salmon's health and growth

-

Study: Omega-3 and zinc is a powerful duo for salmon

-

Fish may turn yellow if frozen too fresh

-

Is it better if food is packaged in plastic or paperboard?