This article was produced and financed by Nofima The Norwegian Institute of Food, Fisheries and Aquaculture Research

First you take a potato

A new method makes it easier to determine which potatoes are best suited for mash and which should rather become potato chips or french fries.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

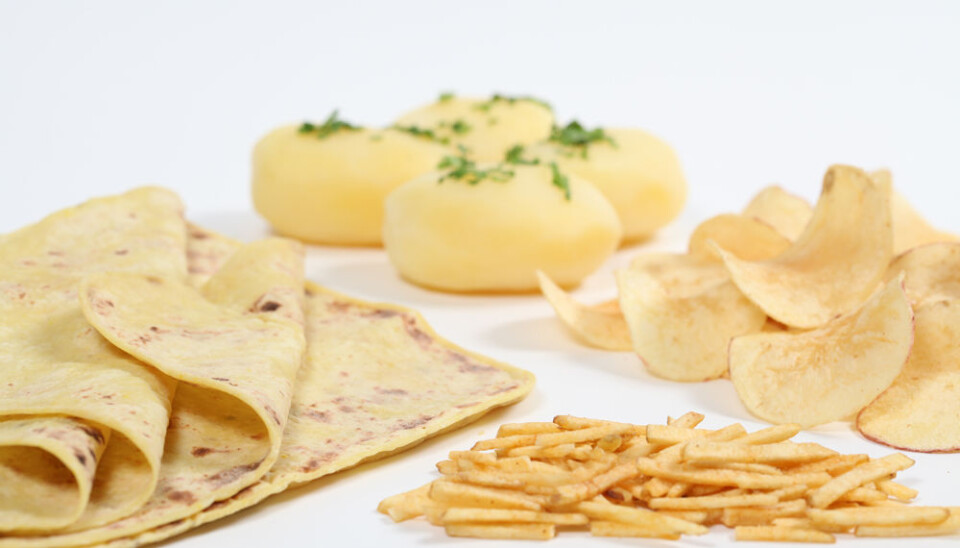

Potatoes are an important part of the Nordic diet. They are typically served boiled for dinner, but also come as chips and french fries, and as potato cake, the Norwegian version of a tortilla.

For producers, the large variations in potatoes' ingredients pose a challenge. A new method gives them better insight into the potato quality.

"It is now quicker and easier to measure dry matter content, which provides us with new opportunities for understanding how different content levels affect quality," explains Nils Kristian Afseth, a research scientist at the Nofima food research institute.

The dry matter content is what remains in a piece of potato after the water is removed.

Afseth has worked with PhD-student Trygve Helgerud on developing the new method, which is based on near-infrared spectroscopy.

A biochemical factory

The content of a potato and its suitability for industrial processing depend on many different things, such as diseases, time of year, growth, weather and storage.

"The potato is something of a biochemical factory. For this reason there are enormous variations in the nutritional content of potatoes between harvests, within the same harvest and even between the tubers on a single plant," says Afseth.

Even if in an ideal world we could be able to control cultivation and storage conditions right down to the individual tuber, there would always be natural biological variation.

Measures every single potato

Dry matter content says a great deal about potato quality. The higher the dry matter content, the less water and the higher the price per kilo for the potato producers. The most common method used by the industry to determine dry matter content is called underwater weight. This is found by weighing a sample in air and then weighing it in water.

"What is actually being calculated is the density of the tubers, and this is used to estimate the dry matter content," says Helgerud.

There are several advantages to this method. It is cheap, user-friendly and relatively accurate for the sample that is taken. The problem is that it is impossible to characterise an entire batch and only random five kilogram samples are taken.

"We have been working on a method based on a technology called near-infrared spectroscopy to estimate the dry matter in raw, unpeeled potatoes on the processing line. The aim is to be able to measure the dry matter of every single potato on the line or when sorting beforehand. This means the producers could exclude extreme variation and sort the potatoes better. In this way, they could achieve a more uniform product quality," says Afseth.

The best potato for potato cake

At Buer Potato Cake Bakery in Askim, they want to achieve the most stable potato quality possible. The most experienced bakers get to decide what the dough needs; this is a craft that demands knowledge. Getting even better quality control has been a top priority for a long time.

"It is possible to correct a dough that has become too sticky, but it affects the flavour. So predictable quality and monitoring of quality are important to us. The tests we have carried out together with Nofima mean that we now have a better understanding of the processes, which means we can make the necessary adjustments earlier in the production process," says Bjørn Olav Drabløs, owner and general manager of Buer AS.

The properties of potato cake dough are determined by many different factors. Variations in the potatoes become multiplied along the way and greatly affect the final quality. In order to understand what affects dough quality in different recipes and process conditions, the material properties of the dough are measured using rheology.

"Here we can compare doughs of different compositions with what the bakery defines as the optimum. This helps us to understand the key factors that give the optimum dough," says research scientist Simon Ballace of Nofima. He has the primary responsibility for building expertise in the new rheology system being used in the project.

Why are some potatoes more suitable than others

The method and length of cooking potatoes affects both the potato cake dough and other uses for potatoes. The aim is to find the best cooking method for different variations of dry matter and starch content, for example.

Investigating potato cake dough is just one part of the potato quality research at Nofima. The researchers also study how sugar and starch in potatoes affects other finished potato products.

They have looked at what is important in potatoes for crisps and chips, and now they are looking at the factors that give the best ready-cooked potato products. For crisps and chips, it is especially important to be able to control the glucose level, from the point of view of both acrylamide and colour.

"At the moment, there is no commercial system for measuring the dry matter content of intact potatoes on the line, but developments so far have been extremely promising and we are now working on also developing this technology further in other projects at Nofima," concludes Afseth.

------------------------

Read the Norwegian version of this article at forskning.no