An article from NIVA - Norwegian Institute for Water Research

How to deal with ballast water

New international requirements for treating ballast water to stop harmful hitchhikers also pose scientific challenges for the testing of disinfection technology.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

More than 80 percent of the world’s raw materials and merchandise is transported by ships. These vessels also carry from 3-12 billion tonnes of ballast water, needed for stabilisation on return voyages with little or no cargo.

Ballast water is recognized as the main vector for spreading organisms to new areas along seacoasts and in watercourses.

There are many well-known examples of aquatic organisms that have survived pumping and storage in ballast tanks. When discharged along with ballast water they can establish themselves in a new suitable environment. The resulting introduction of alien organisms can be devastating on local ecosystems.

The UN’s International Maritime Organization (IMO) has attempted to mitigate the problem by proposing maximum accepted limits on contents of bacteria, algae and zooplankton in ballast water before it can be discharged in new areas.

“This will reduce the risk of contamination by new organisms,” explains Researcher Stephanie Delacroix at the Norwegian Institute for Water Research (NIVA).

The IMO convention on the treatment of ballast water was adopted in 2004. It prohibits ships from discharging ballast water within certain distances from specified coastal zones. When the IMO Ballast Water Management Convention will be ratified, this ballast water will also have to be disinfected by certified equipment before being released.

First international authorised land-based full scale testing facility

Such equipment can only be approved after exhaustive testing in accordance with stringent regulations. NIVA’s Marine Research Station at Solbergstrand in the narrow Drøbak Sound, a little south of Oslo, became the first internationally authorised full scale testing facility for both marine water and brackish water in 2005.

Tests are implemented at Solbergstrand in small scale as well as in huge tanks with capacities for several hundred cubic metres of water. Researchers from NIVA also perform shipboard testing before final equipment authorisation can be granted.

Several Norwegian companies have developed purification equipment for ballast water.

“Since 2005, we’ve tested 12 different water treatment technologies aimed at meeting the IMO discharge requirements,” says Delacroix.

Six of these have been given final certification and are now available on the world market. The others are undergoing IMO evaluation’s process for type approval.

How are organisms killed in ballast water?

Most ballast water purification installations disinfect water with chlorine or ultraviolet (UV) radiation after particles are removed from the water by filtration.

A number of other technological solutions can be used, including vacuums, pressure drop, heat, ozonation, electrolysis or the removal of oxygen by substituting nitrogen. Such methods and others can be used individually or in various combinations.

But the technologies are required to document that they have no toxic effects on the marine environment once the water is discharged.

American regulations

“The equipment for treating ballast water must be shown to meet the IMO’s standards before it can be mounted aboard ships. We are now developing our testing methods to satisfy new United States requirements and for testing in freshwater,” says Delacroix.

The American regulations were implemented in June 2012. That means ballast water treatment technology that has been tested and authorised in conformity with US standards is mandatory aboard any ship needing to release ballast water in American waters.

Various laboratory analysis methods are used to document that the maximum concentrations of living organism at discharge are not exceeded for different size groups identified by IMO.

US authorities currently operate with a tougher interpretation than the IMO of rules to curtail invasive aquatic organism viability. The IMO deems it sufficient if organisms are prevented from regenerating. American inspectors on board ships will go further by demanding that the destruction of the organisms is total immediately at discharge time. Organisms must be dead in ballast water intended for discharge American waters.

This is a problem, especially for disinfection technology using UV radiation as an essential component. UV energy works primarily by damaging DNA. It takes far heavier doses of UV to kill an organism than to knock out its reproductive capabilities.

Operating with quickly fatal UV doses requires unrealistic amounts of energy in equipment on board vessels which need to treat several hundred cubic metres of water an hour.

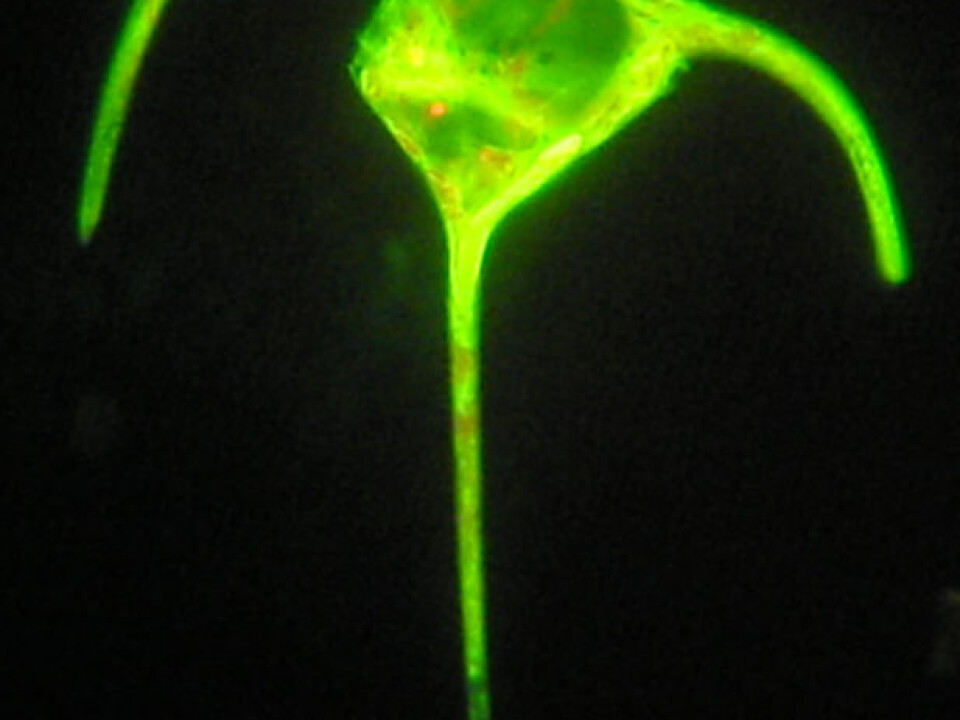

“We’ve used a method that makes active cells absorb colour compounds which fluoresce with an intense green light if they are still intact and contain active enzymes,” says Delacroix.

This tell-tale dye is not absorbed in dead cells, which lack active enzymes. The method, however, gives false positive results when the water in treated with UV radiation. This is because the enzyme remains active a few days after being irradiated, even though the DNA in the cell is destroyed and it can no longer reproduce.

“That’s why we’ve supplemented these efforts with regeneration attempts to ascertain whether the cells are dead. But these tests have not been cleared by the US authorities because some algae cannot be cultivated in laboratories,” explains Delacroix.

This problem is still a topic of discussion between the USA and the EU. Equipment suppliers are at a loss regarding what to do. They are looking to researchers to devise innovative, faster methods that show whether algae are dead or dying after treatment.

Developing new test methods

“Procedures and methods of testing for living organisms in ballast water need to be continually developed to meet the new, rigorous demands,” says Delacroix.

Research will among other things have to develop quick and reliable analysis methods which ascertain the number of living organisms before and after treatment.

“We currently utilise many of the same analysis methods for testing ballast water as for drinking water. Several of these are too slow to be acceptable for ships in port,” says Delacroix.

Vessels might be held by port authorities until water in ballast tanks is inspected and given the thumbs-up.

“Every hour of delay at dock can cost ship owners around $1,500. So there’s a real need to acquire faster methods covering a broader spectrum of organisms simultaneously,” she points out.

Testing in freshwater

For approval of ballast water treatment systems, land-based testing only in two of the three water qualities as defined by IMO was required: seawater, brackish water or freshwater.

Most have tested their technology for brackish water and seawater, but very few have performed testing in freshwater so far.

“It turns out that equipment constructed for one type of water doesn’t necessarily work for the others,” says Delacroix.

For instance, systems using electrolysis don’t work in freshwater unless there’s a certain concentration of salt in the water.

Testing of equipment for freshwater is essential because many busiest ports in Asia (Shanghai, Shensen), Europe (Antwerp, Bremerhaven, Hamburg, and the Baltic Sea ports) and the USA (Great Lakes) are composed of freshwater.

Certain cases involving the spread of invasive freshwater species through ballast water have been catastrophic. The zebra mussel is a freshwater mollusc that is native to the Aral, Caspian and Black Seas.

“This species has done immense damage to watercourses in Europe and the USA,” says Researcher Markus Lindholm.

“It starts colonies in water pipes and clogs up water supplies and cooling systems. The zebra mussel has not been observed yet in Norway but we fear it can be spread by fishing gear and boats that have been in watercourses further south in Europe,” he says.

The Chinese mitten crab (Eriocheir sinensis) is another undesired alien in our lakes and rivers. It probably came to Europe in ballast water from Asia. The crab burrows into riverbanks and causes serious erosion. It also competes with native aquatic species and can have an impact on stocks.

The special attribute of this crab is that it normally lives in rivers, but it spawns in brackish water where they meet the sea. This enables the larvae to be spread to seawater. In Norway it has been observed at the mouths of several watercourses on the south coast of Norway and along the Oslo Fjord.

“We’ve developed methods for harvesting and cultivating organisms from lakes and rivers near Solbergstrand as a step in testing treatment technologies for freshwater,” says Delacroix.

“We also had to adapt eco-toxicological methods for testing possible toxins which could harm fish, crustaceans and algae in freshwater when the water is discharged. We’ve recently achieved this,” she explains.

Based in part on NIVA’s documentation for land-based and shipboard tests of various ballast water treatment systems developed from all part of the world, Det Norske Veritas (DNV) and IMO can certify types of ships’ treatment technology. DNV issues certification on behalf of the Norwegian Maritime Authority.