THIS ARTICLE/PRESS RELEASE IS PAID FOR AND PRESENTED BY the Norwegian University of Life Sciences (NMBU) - read more

Making the most of forestry waste

Fungi growing on waste from the forest industry can produce oil which can be used for our food and animals’ feed, as well as for biofuels. However, the production of such oil is costly. Producing additional valuable bioproducts in the same process may solve this challenge.

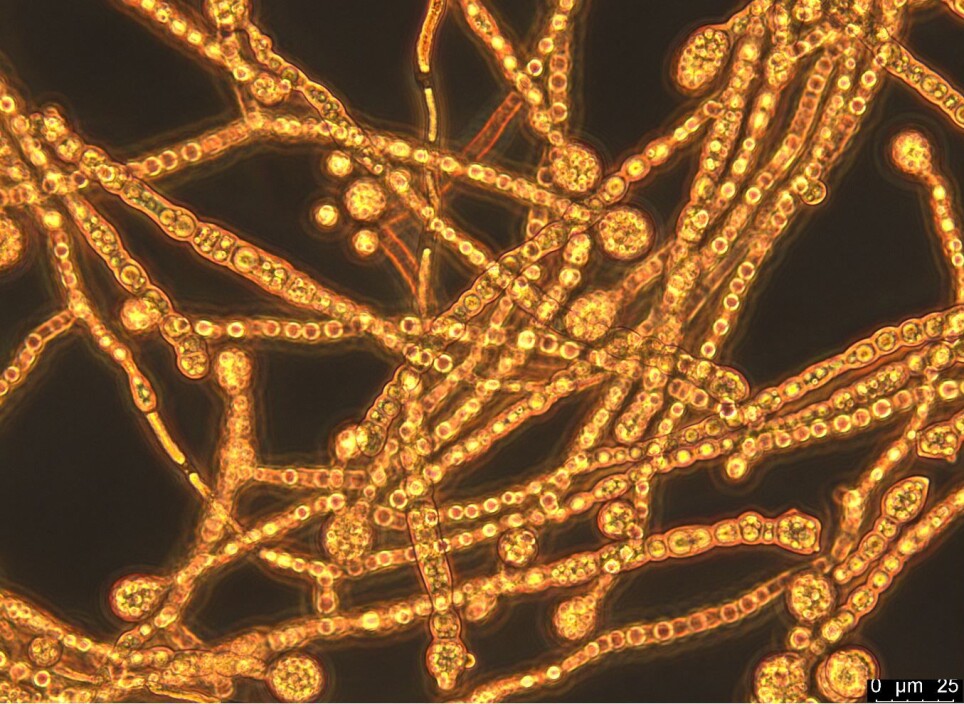

Fungi is more than mushrooms, mildew and mould. With the right tools we can use it as food, medicine, and biofuels – and numerous other things.

The centre for environment-friendly energy research (FME) Bio4Fuels is based at the Norwegian University of Life Sciences, with the goal to use the by-products and waste of the Norwegian forest industry to produce biofuels. Part of this research is using lignocellulose from woody biomass to grow fungi, in order to produce oils that can be used as biofuels or a part of human and animal nutrition.

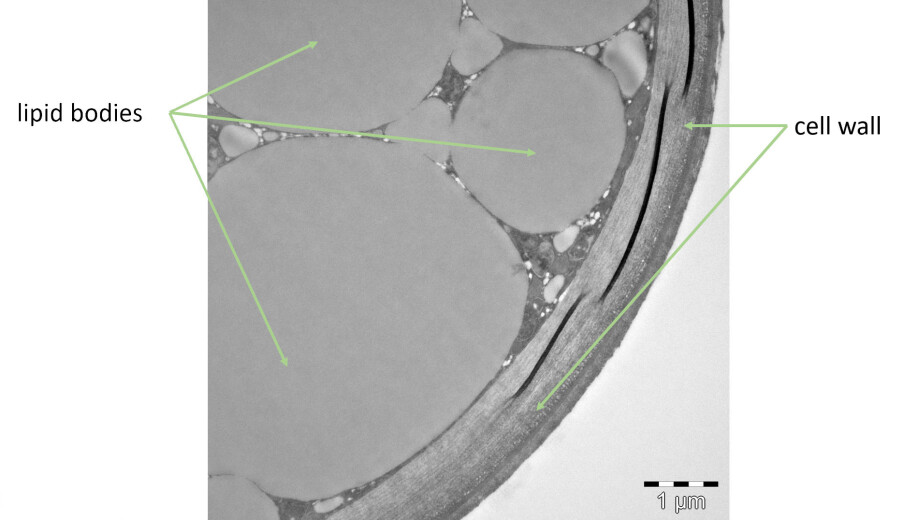

However, this bioproduction is costly. Any process solely producing lipids is not economically viable, and NMBU researchers see the need for making more use of the process, producing more valuable components at the same time. Now, they have discovered that co-production may be a solution, as other high value components can be produced in the same fermentation process.

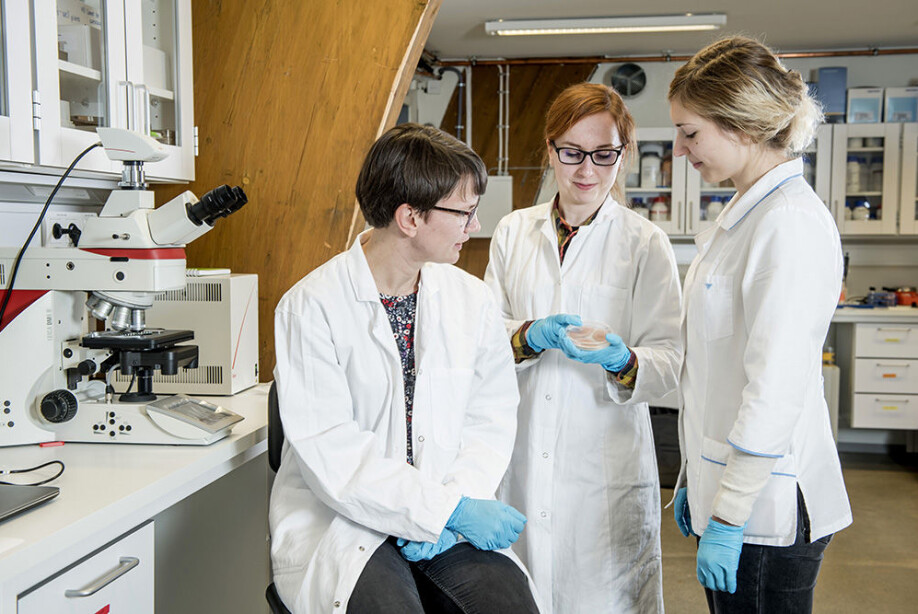

Simona Dzurendova, the PHD researcher responsible for the work, explains:

“Fortunately, in addition to lipids, fungal biomass contains valuable biopolymers, called chitin and chitosan. These can be used in medical applications, for wastewater treatment, agriculture and food industry. In addition, fungal biomass can accumulate polyphosphates, which can contribute to recovering and recycling phosphorus and use it as biofertilizers in agriculture.”

Novel methods

In her doctoral work, Simona wanted to modify the process in order to get the highest amount of biomass and lipids from of the resources, and different conditions and strains of fungi were tested – aiming to find the best fungal candidate for co-production.

“Some of the fungi can also produce carotenoid pigments, yet another product that would bring value to the bioprocess, as it can be used as food additives and colorants,” she explains.

Another innovative aspect of this work was the use of vibrational spectroscopy in combination with micro-cultivations, allowing for extensive screening of fungi based on low biomass volumes. In this way, the researchers could see which types of fungi contained the valuable components, with minimum resources and less time used. Because of these methods, the researchers could monitor the whole composition of the samples and assess what types of fungi were best for different applications.

“The fungal biomass can be used as it is - for example for animal feed. It is rich in proteins, lipids and minerals, so it can serve as nutritious meal for fish. Alternatively, the biomass can be broken down into several bioproducts,” Simona Dzurendova says.

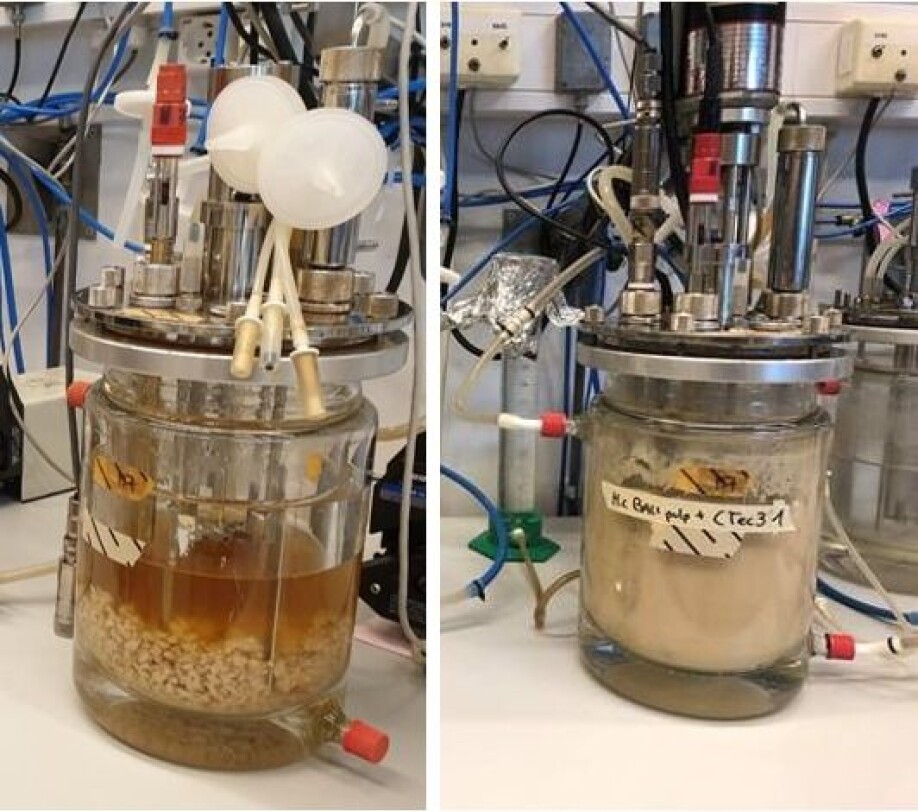

The concentration of the growth media components was also tested thoroughly, uncovering the specific effects of the different media components on the fungal biomass. The trials have so far been done on a small lab scale, but with bioreactors at NMBU and at other facilities the trials can eventually be conducted with up to 25 litres at a time.

“This is the next step, as we now know what fungi and conditions are best for the upscaling in bioreactors,” Simona explains.

As the work uncovered the best growth media and fungal strains for the co-production it can be seen as the groundwork for an upscaling of fungal fermentation with the aim to co-produce lipids and biopolymers. Simona Dzurendova’s work will be a background for newly funded project – LIGNOLIPP.

“Combining the utilization of rest materials as substrates for fungal biorefineries and the co-production of high value biopolymers in addition to lipids can greatly enhance the economical sustainability of the whole process,” Simona says.

See more content from NMBU:

-

Shopping centres contribute to better health and quality of life

-

We're eating more cashew nuts – and the consequences are serious

-

Do young people with immigrant parents have better health?

-

Who’s picking your strawberries this summer?

-

Can coffee grounds and eggshells be turned into fuel?

-

Rising housing costs fuel inequality in Norway