THIS ARTICLE/PRESS RELEASE IS PAID FOR AND PRESENTED BY Nofima The Norwegian Institute of Food, Fisheries and Aquaculture Research - read more

This sensor is going to make sure that the cheese you buy always tastes the same

Everything is now in place to better understand the relationship between the quality of the cheese and the raw materials and processing conditions.

The dairy Tine Meierier Jæren produces the majority of Norway’s best-selling cheese – Norvegia.

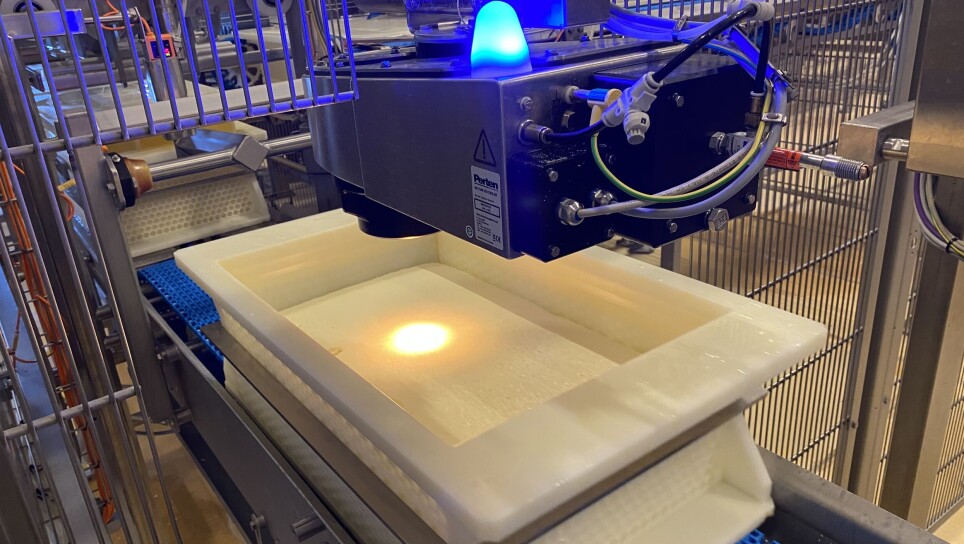

A NIR sensor has been installed on the dairy’s production line, using light rays to measure the fat and dry matter contents of the passing cheese.

“Producing cheese with a consistent quality is a challenge, and there are several things that may cause the quality to vary," Kjetil Holstad says. He is head of the R&D department at Tine Meierier Jæren.

He further explains that the contents of the milk used varies with the breed of cow, season, weather and feed, as well as lactation – that is, how long it has been since the cow calved.

Interruptions in production can also lead to variations, because it affects the process that takes place in the cheese.

Norway's best-selling cheese

More milk is needed to make firmer cheese. It takes ten litres of milk in order to produce one kg of Norvegia. By comparison, Brie needs less, while Parmesan requires more.

Several thousand tonnes of Norvegia are sold every year, and the cheese plays an important role in regulating the milk market. More milk is available during certain times of the year, and more Norvegia is produced during these times of high milk production – resulting in the cheese spending a longer time in storage.

“Storage time affects the need for dry matter. Norvegia becomes softer during storage as the protein is broken down, so more dry matter is needed for longer storage times. We also know that customers reject Norvegia that is too dry and firm,” Holstad says.

From spot checks to measuring all cheese

“Previously, we only did spot checks where we manually sampled one in every 100 cheeses. The NIR sensor now enables us to measure all the cheeses directly on the production line and collect enormous amounts of data, which we use to gain insights into quality variations, including the nature of the variations, why they occur, and what we can do to ensure more consistent quality,” Holstad says.

The NIR sensor evaluates the cheese at the end of the production cycle.

The primary objective is therefore not to make changes to the final product, but to use the measurements to observe and understand how different manufacturing and raw material parameters affect its quality.

The next step is to apply the results from the NIR measurements in the control system in order to make automatic adjustments in the process based on the milk quality.

Analyses large amounts of data

A comprehensive dataset is needed to unravel the links between raw materials, processing conditions and cheese quality. In addition, expertise and investment in data management and analysis are also needed. TINE has therefore collaborated with both Intelecy and Nofima for several years, with the aim of gaining a better insight into the process.

“The first analyses that include data from the NIR sensor are already underway, but it is necessary to collect data over a long period of time to account for variations in raw materials that change between seasons and from year to year. We also need to test the effect of different processing conditions by making controlled changes in, for example, temperatures and time spent in the different production stages,” senior scientist Ingrid Måge at Nofima says.

The collaboration with Nofima has focused on measurement technologies and multivariate data analysis, with particular attention on how combining data from both laboratory analyses, process sensors and processing conditions can provide a better understanding of the relationship between variables in the process.

Intelecy specialises in time-series analyses and provides a solution for ‘no code’ industrial machine learning. They have focused on detecting patterns and insights from sensors with continuous data streams, for example on temperatures and pH values.

“In the beginning, we kept these collaborations separate to compare the results. But even though Nofima and Intelecy have used slightly different data and methods, they came to several consistent conclusions,” Kjetil Holstad says.

This article/press release is paid for and presented by Nofima The Norwegian Institute of Food, Fisheries and Aquaculture Research

This content is created by Nofima's communication staff, who use this platform to communicate science and share results from research with the public. Nofima is one of more than 80 owners of ScienceNorway.no. Read more here.

See more content from Nofima:

-

Red algae grown in wastewater from fish-farming facilities could become sustainable salmon feed

-

Pumpkins are good for more than just Halloween decorations

-

This is how temperature affects a salmon's health and growth

-

Study: Omega-3 and zinc is a powerful duo for salmon

-

Fish may turn yellow if frozen too fresh

-

Is it better if food is packaged in plastic or paperboard?