THIS ARTICLE/PRESS RELEASE IS PAID FOR AND PRESENTED BY University of Oslo - read more

Pursuing better, cheaper and more environmentally friendly batteries

Batteries are essential for a future with more renewable energy. Visit the lab where researchers are developing what might be tomorrow’s battery technology.

The world is being electrified. As a result, we have become increasingly dependent on batteries. The endless flow of new gadgets in recent decades would not have been possible without them, and now the car fleet and ship traffic are increasingly powered by electricity.

Batteries could be the next big Norwegian industrial adventure, according to Confederation of Norwegian Enterprise (NHO).

In Norway at least four huge battery factories are being planned. In Europe more than thirty. The main products will be lithium-ion batteries, a technology that first came on the market in 1991, and which has been an important prerequisite for all the small electronics and the electric cars we now see all around us.

"In the consumer market, there is a continuous pursuit of making batteries smaller and more efficient," says Vebjørn Bakken, director of UiO:Energy.

It is not without reason that size has been so important.

"You want to have space in your car. You want the car to carry not only the battery, but you and your family as well," says Associate Professor Alexey Koposov at the Department of Chemistry.

Research is being done worldwide to make lithium batteries even better and safer. Many are looking for other solutions, new battery technologies that could become tomorrow's batteries. They have much more than gadgets and everyday electronics in mind.

"What's coming now are really big battery systems connected to the electrical grid. Size and weight are then no longer critical. The important factor is as much capacity as possible," Bakken told Titan.uio.no.

This is closely related to the focus on renewable energy from the sun, from the wind and other sources.

"Sun and wind give intermittent energy production depending on time, season and the weather. This leads to an increasing need for energy storage," Bakken says.

It’s not all chemistry

"I think the battery research is one of the fields developing the fastest right now. Particularly when it comes down to chemistry," Koposov says.

Batteries aren't just about chemistry, but you can't get far without it. Just look at the definition of a battery at Britannica: A battery is a device «that converts chemical energy directly into electrical energy».

"Batteries wouldn't be possible without dedicated materials, but adopting those is about much more than just chemistry. The battery is a system that uses materials and is based on chemical principles, but it is also great engineering work to put them together and make them safe.

"Not least in how to charge them, which is a question I as a chemist don't think much about," Koposov tells Titan.uio.no.

It does not help to make the best battery in the world if it is not possible to charge it and fill it with energy. And, of course, to bring the energy back out.

Fears shortage of lithium

Some people fear that there will eventually be a shortage of lithium, and without lithium, you cannot make lithium batteries.

"What can at least happen is that the price of lithium goes up because huge factories are being built all over Europe," Koposov says.

Another problem that has received a lot of attention is the use of cobalt in electric car batteries. Much of the cobalt originates from the Democratic Republic of Congo, and this extraction has been criticized by both human rights and environmental organizations.

Therefore, research is being done to replace lithium with sodium or other elements.

"Sodium is a material we can easily obtain in Europe. The desire to make batteries more sustainable is one of the driving forces behind this development," says Koposov.

From lithium to sodium

In the periodic table, sodium is located just below lithium in the column on the far left. That means they have properties similar to each other, but it's not just taking out lithium and putting sodium in instead.

"The anode in lithium-ion batteries is almost always made of graphite, but it doesn't work at all for sodium," says Doctoral Research Fellow Anders Brennhagen.

In a lithium battery, the lithium ions settle between the layers of the crystal structure of graphite without any major changes in the structure itself. Brennhagen works with sodium batteries and must use materials other than graphite in the anode. The problem is that these materials change their structure when receiving the ions.

"My materials can absorb much more sodium ions and therefore have a much higher capacity, but since there are such large changes in the structure of the material, it is difficult to get the capacity to be stable over many cycles of charging and discharging," Brennhagen says.

In his PhD, he hopes to get closer to a solution. If he succeeds, the rewards can be great.

Cheaper and more sustainable

“Sodium-ion batteries can become a more environmentally friendly alternative to lithium-ion batteries. They can also become cheaper and more sustainable," Brennhagen says.

In the earth's crust, there is more than 1000 times more sodium than lithium, and sodium can be found everywhere. You do not become dependent on the few countries that have a lot of lithium. Sodium will probably not replace lithium, but sodium batteries may have their advantages in some applications.

"Lithium-ion batteries will in all likelihood always have higher energy density than sodium-ion batteries, but you may not always need the very best. Sometimes price has a lot more to say, and then sodium-ion batteries can be better," Brennhagen says.

"For now, lithium-ion batteries are so cheap, and that technology is well developed, so it's easier to go for it."

At the same time, the sodium battery technology has come far enough to be ready if the opportunity arises.

"If anyone wants to make an industry with sodium-ion batteries now, it can be done. There are already prototypes of well-functioning sodium-ion batteries, but it takes a lot of investment in both material and battery production for it to really be able to compete with lithium-ion batteries," Brennhagen says.

He himself has to be patient.

"The materials I work with are still at an early stage of research. It will at least take ten years before it is on the market," Brennhagen says.

Calcium – double charge

If we return to the periodic table, In the column to the right of lithium and sodium lies calcium. Calcium is even more abundant in the earth's crust than sodium.

"There is more than enough calcium in the world, so there is certainly no problem with access to materials. Calcium is also a well-known substance," says Vebjørn Bakken.

The chemists have several reasons to take a closer look at calcium as they search for new battery technologies.

"The great advantage of calcium is that for each atom, two charges are moved. With lithium and sodium, there is only one. The problem with calcium is that the chemistry becomes more complicated. The chemistry changes a little bit, and this little bit is enough for us to need to reassess all these processes that are taking place," Alexey Koposov says.

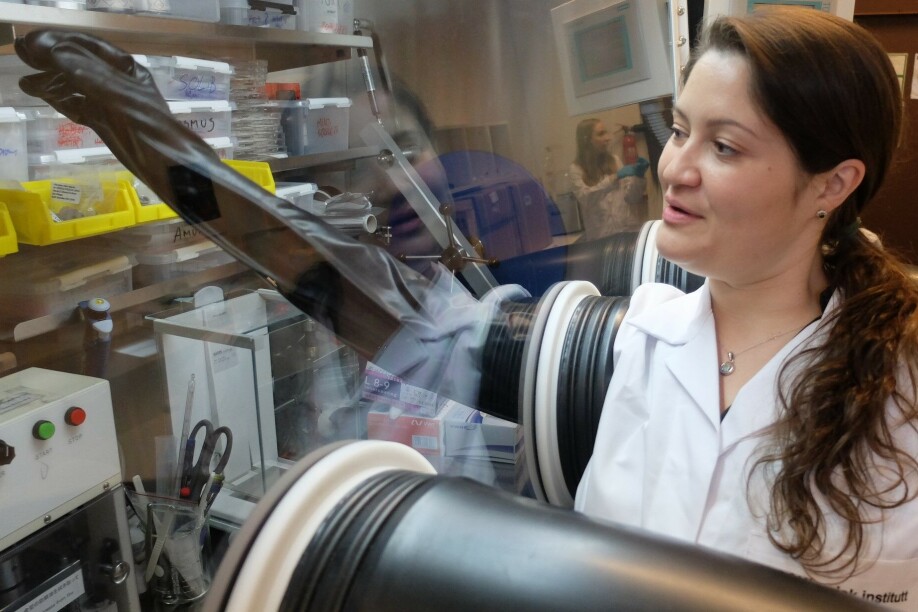

"Calcium is also much less dangerous than lithium and sodium. Calcium is not explosive," says researcher Carmen Cavallo of the Center for Materials Science and Nanotechnology.

Her challenge is to build a complete battery with anode, cathode and electrolyte. The first step is an anode that works with calcium.

"Calcium is slightly larger, heavier and slower than lithium and sodium. The biggest problem, therefore, is moving calcium back and forth between anode and cathode," Cavallo says.

Norwegian silicon

To make it easier, she can mix calcium with other substances. There are several candidates, but Cavallo is going for silicon.

"I will make a silicon-calcium alloy to solve the slow movement of the calcium ions and further reduce the costs. Norway delivers one of the best raw silicon materials. It makes the whole process cheaper," she says.

"This technology is at a very early stage and for now it is fundamental basic research. I hope to have a prototype by the end of next year, but a complete battery will not be ready until 2024 at the earliest," Cavallo says.

Even then, it’s a long road before it eventually finds its way into the battery market. She comforts herself by the fact that there were decades of research before lithium-ion batteries saw the light of day. Cavallo imagines that calcium batteries can be useful for many technologies, especially for marine applications.

"Calcium batteries can store twice as much electricity as lithium and sodium, so I primarily aim for use for big devices," she says.

Solid-state batteries – no fire hazard

Cavallo has several challenges ahead. She wants to replace the liquid electrolyte with a solid one. This will improve the safety of the calcium batteries. Who hasn't been frightened by stories of mobile phones exploding? In such cases, electrolyte from the battery is the culprit.

"Current lithium-ion batteries have flammable electrolytes. I think most electric car manufacturers would prefer lithium batteries in a solid form," Alexey Koposov says.

"Liquid electrolyte cannot withstand contact with air. If a battery accidentally cracks or breaks, the electrolyte could catch fire," Cavallo says.

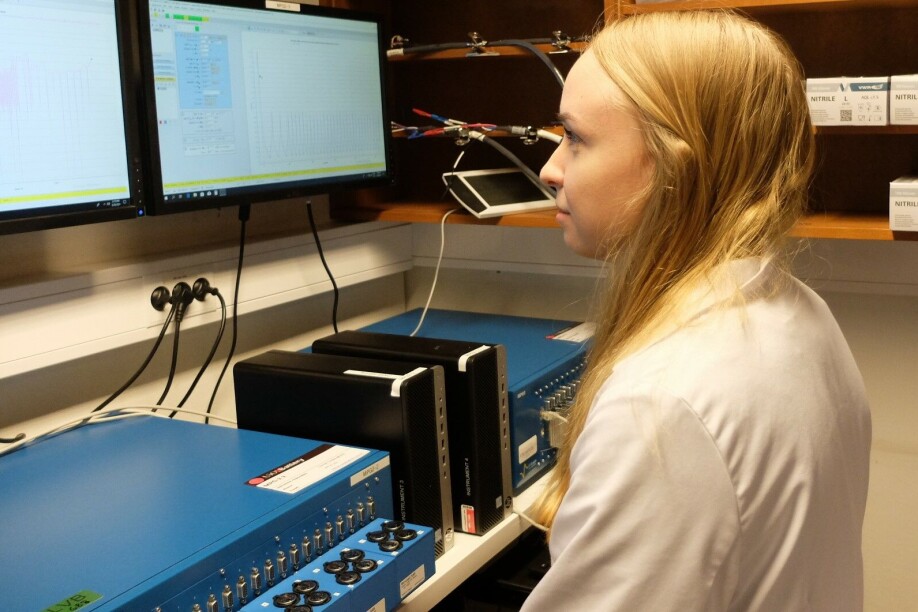

PhD candidate Carina Geiss at the Department of Chemistry is working on finding a solid form of electrolyte.

"I think we can get pretty close to what's possible in a liquid electrolyte, and that's good enough," Geiss says.

Spaghetti sandwich

For this, she makes use of compounds called polymers. These are chemical compounds consisting of chain-shaped molecules and they are the main component of plastic products.

"My polymer electrolyte looks like a thin membrane, but when you take a closer look at it, it consists of different polymer chains. They almost look like spaghetti," Geiss says.

When heated, or if she adds the right ingredients to the material, these chains start to move. Like long strands of boiled spaghetti that moves in waves up and down. As they move, small pockets appear between them where the ions can stay.

"When the polymer chain moves, it constantly creates new voids, new pockets where an ion would rather be, and thus it jumps. The more the chains move, the more they encourage the ions to jump," Geiss says.

The ions will be happy to get from one side to the other, depending on whether you are using energy (discharging) or if you are charging the battery.

"The ions follow the chemical potential. Just like water runs downhill and not up. Charging a battery can be compared to forcing water to run upwards. When you use the battery, you just let the water run down," Geiss explains.

To make this as efficient as possible, she intends to make a battery sandwich by pressing together the anode and cathode, with the electrolyte melted in between.

"It's almost like a sandwich, where the electrolyte is like a slice of cheese. By melting the electrolyte into the pores of the anode, we achieve the best possible interface, and the thinner the cheese slice, the shorter the path for the ions is," Geiss says.

A revolution

She also has to mix in other materials in her polymer chains because polymers have quite poor conductivity.

"If we mix pieces of ceramics or other materials into the polymer chains, we can get the best of two worlds. We get a good interface between the different parts of the battery, and we get better conductivity," says Geiss.

Some car manufacturers have said that solid-state batteries could be seen in electric cars as early as 2025 if everything goes according to plan. When the solid battery comes with full force into the market, the world will no longer be the same.

"When solid batteries become generally available, there will be a small revolution. It will give a boost to the range of electric cars and electric boats. Even aircrafts will then be much more within the range of batteries," Vebjørn Bakken says.

Due to the dangers associated with liquid electrolytes, today's batteries must be packed well when used in, for example, cars. Thus, they take up more space, and they weigh more.

"The great advantage of solid electrolyte is that the battery cannot leak. They are not explosive. They are much safer, and you can save both space and weight in the electric car," Geiss says.

Norway has advantages

It is not easy to predict what the battery industry will look like in 10, 20 or 30 years, but the researchers do not doubt that new technologies will come.

"It is very difficult to predict such breakthroughs, but there are so many people working on this now, that I am sure they will come. I think we will have sodium-ion batteries in use for stationary storage in ten years. I hope that we by then also will have lithium-ion batteries in solid form," Alexey Koposov says.

"I think we're going to see a lot of different niches where there are different features of the batteries that are emphasized. There will be room for quite different types of batteries. This is a huge market with many different uses," Vebjørn Bakken says.

He also believes Norway can find a place in this market and mentions three advantages Norway has:

"The largest of them is the supply of clean energy, in terms of renewable electricity. Even though there will be discussions as things develop, we will surely need significantly more electricity. In the long term, floating offshore wind may be the best option in Norway, where the conflicts are more limited than onshore wind. Solar energy will also contribute, even in this country. "

"The other advantage is that we have plenty of available space, and battery factories take up lots of area. Thirdly, they need cooling, and in Norway we generally have good access to cooling with water," Bakken says.

Contributing to a greener world

The world needs more, better and more environmentally friendly batteries. For Carina Geiss, Carmen Cavallo and Anders Brennhagen, this is part of the motivation for enduring the meticulous work and the many long days of experiments in the laboratory.

"That's the main reason I started battery research. I wanted to work on something in renewable energy to contribute to a cleaner future," Brennhagen says.

"It is challenging but thrilling to help facilitate the technology of the future. I want to be part of the change that the world needs to make and move towards greener energy solutions. For my and all the future generations." Cavallo says.

As with all research at such a fundamental level, where they have to zoom in on the very smallest details of the chemical processes, coming up with new products is not done in an instant.

"We still have a long way to go, but it's exciting to be involved in driving the development towards better, greener and more sustainable batteries," Geiss says.

See more content from the University of Oslo:

-

AI makes fake news more credible

-

What do our brains learn from surprises?

-

"A photograph is not automatically either true or false. It's a rhetorical device"

-

Queer opera singers: “I was too feminine, too ‘gay.’ I heard that on opera stages in both Asia and Europe”

-

Putin’s dream of the perfect family

-

How international standards are transforming the world