An article from Norwegian SciTech News at NTNU

Marine technology for extreme conditions

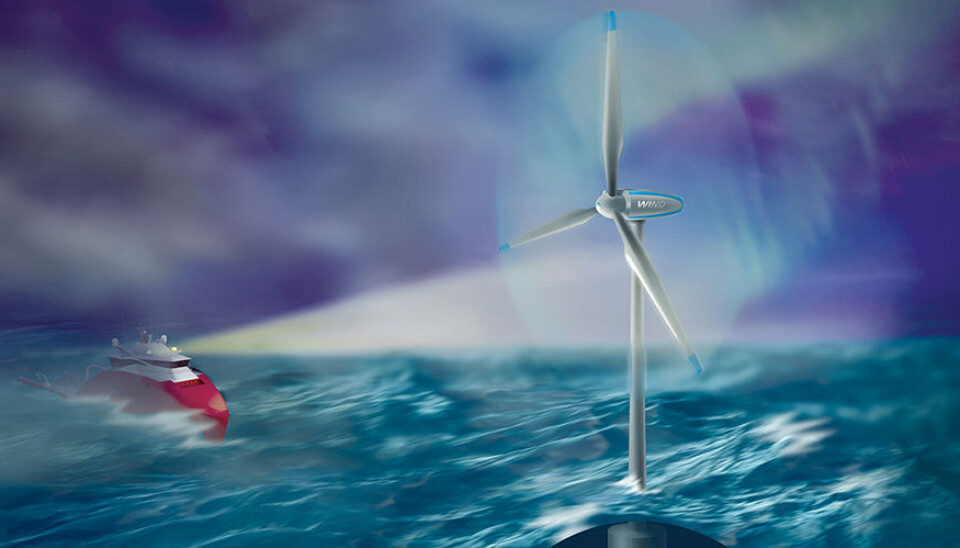

Tomorrow’s maritime technology must be able to handle extreme conditions during Arctic and deep-water operations. A new research centre designed to develop these technologies holds promise for Norwegian industry.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

With a newly opened Marine Operations research centre in Ålesund, Norway aims to spearhead maritime research that addresses the ocean’s most extreme conditions.

Oceans cover 70 percent of the Earth’s surface, and 80 percent of the ocean is deeper than 3,000 meters. Norway administers a sea area six times larger than its mainland.

Great potential exists for developing new maritime “Blue Tech” industries and expanding current industries. But the maritime environment also holds great challenges.

Harsh northern weather conditions for conducting operations include ice, low temperatures and deep waters.

Merger in the future

Aalesund University College is part of the big merger between NTNU and university colleges in Gjøvik, Sør-Trøndelag and Ålesund. The Marine Operations SFI gives everyone a sense of the merger will be like.

“The award of this SFI is strong recognition of the excellent and internationally regarded research going on at Aalesund University College. The collaboration in this centre is also an example of the mutual benefits that the upcoming merger will offer,” says NTNU’s Rector Gunnar Bovim.

NTNU currently hosts five SFI research centres, and is involved in nine other centres.

Relevance for industry

The SFI project is an example of beneficial cooperation between the business sector and research and educational institutions, and Associate Professor Karl Henning Halse at Aalesund University College believes the impending merger will affect the project positively.

“The different research environments complement each other well. Our priorities are both academic research and industry-oriented applied research, so we are confident that our work will be relevant to industry,” says Halse.

The Marine Operations SFI will develop new tools, technologies, prototypes and training for safe and effective installation and maintenance of ocean structures in extreme waters. Examples include the deepwater subsea installation of offshore wind turbines, mineral extraction from the seabed and Arctic operations.

Simulators for research

A simulator for offshore training is central to the project. The simulator is currently used primarily for training personnel who will perform installations and repairs offshore. Eighty per cent of all offshore accidents are due to human error. It is important for workers and researchers to be able to practice in a simulator with challenging assignments before any approaches are implemented far offshore.

Now the simulator will be developed further so that it can also increasingly be used for innovation.

“We’ll use the simulator to rethink and find new ways to perform operations using it. For that we need to develop better computational models that can generate faster calculations. This will enable us to carry out experiments in real time and to quickly calculate how much load a tool can tolerate, for example,” says Halse.

He adds that a strength of this project is that all the stakeholders are connected to research, and all participants in the business chain are linked. In relation to the merger process, this is a good testing ground for building effective collaborative environments across institutions.