An article from Norwegian SciTech News at NTNU

Recycling aluminium, one can at a time

Recycling is the best way to reduce that carbon footprint – but manufacturers and recycling companies will have to plan carefully to avoid problems with impurities that accumulate in recycled aluminium over time.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

An aluminium beverage can is a true technological marvel.

It’s lightweight and strong, so that it adds little to the cost or weight of shipping beverages, and protects them along their journey.

It chills quickly, to the delight of retailers and consumers alike.

Its smooth, rounded surface makes a perfect billboard for advertising the can’s contents. Consider the red can that’s graced with white script, underscored by a curving white line. An estimated 94 percent of the world’s population knows at a glance what’s inside: Coca-Cola.

And best of all, aluminium cans are eminently recyclable – Europeans recycled 64 percent of all aluminium drink cans in 2009, while North Americans recycled 57.4 percent during the same year. Recycling the aluminium in cans to make new cans takes just 5 percent of the energy needed to produce primary aluminium for the same purpose, and offers an important way to reduce the carbon footprint of using the metal, experts say.

Impurities a problem

But the recycling of aluminium cans involves a very tricky aspect that could cause the entire process to be derailed.

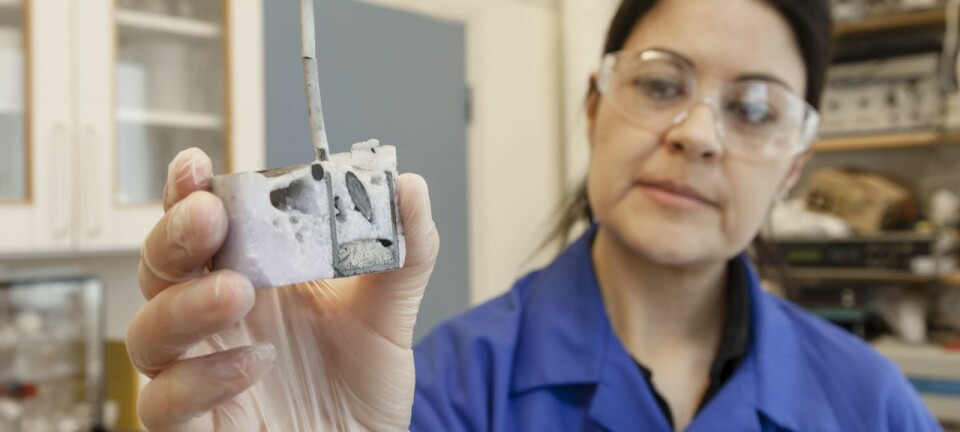

Every time a used can gets melted down into a molten puddle of silvery aluminium, it introduces unwanted hitchhikers into the mix: impurities, either from the composition of the can itself, from the lacquered finish, or from the trash that people sometimes tuck inside.

Sometimes the impurities even come from dust or dirt that may have accumulated on the can somewhere along its journey from your mouth to the recycling facility.

- Right now, with recycling rates where they are, the system works and the impurities normally don’t affect the ability of the recycled aluminium to be made into new cans, says NTNU researcher and PhD candidate Amund Løvik, in NTNU’s Industrial Ecology Programme.

However, if recycling rates increase to 75 percent, for example, then the amount of impurities in the cans will increase – by as much as 135 percent, Løvik and his supervisor, Daniel Müller say. And that could cause problems with the quality of the recycled material.

It’s not that the cans would be unsafe to use, but that the impurities would change the quality of the aluminium to the point where it didn’t have the characteristics needed to actually manufacture a can. The worst case would be that the metal could no longer be recycled into cans or for other uses.

Secret recipes for making cans

While Løvik and Müller can estimate how much impurities will increase as cans are recycled, they do not have any actual information about impurity levels in cans now – in part because it is considered a trade secret.

The industry “all have their own secret recipes,” for making aluminium cans, Müller said.

The pair were able to make good predictions, however, of how impurity concentrations may change over time when changes occur in the system.

Recycling causes impurities to accumulate

Løvik and Müller developed a simple computer model to figure out how these impurities accumulate over time and how recycling rates will affect the amounts of impurities in the recycled products.

Their model relies on a concept called “steady state impurity concentrations.”

Think of it like this: when cans get recycled with their impurities, those impurities are incorporated in the new cans that are made from the recycled mix.

Then, when these recycled cans are recycled again, they bring not only the impurities that are in the actual metal (from the previous recycling mix) but new impurities from the lacquer on the can, or the dust on the outside, or the trash on the inside.

As cans are recycled over and over again, the amount of impurities in each new re-recycled can will increase with each recycling loop.

Impurities eventually reach equilibrium

But because some cans are lost – tossed out in the trash, never to be recycled again – new cans made from fresh aluminium will replace them, lowering the percentage of unwanted impurities in the recycled aluminium mix.

At some point, this loss of old, contaminated cans that are replaced by new, relatively pure cans allows the system to reach equilibrium, meaning that the percentage of impurities in the mix never rises above a certain level.

Müller says impurities in cans are like a water in a bathtub with a little leak in the bottom – the more water the tub contains, the more water will exit the tub at a given recycling rate; the impurities rise to a certain level but never higher because there are always cans with impurities that “leak” out of the recycling system. That’s the steady-state impurity concentration.

Müller says the levels of impurities in recycled cans right now are OK, because recycling rates are well below 100 percent. But increasing recycling rates is everyone’s goal, he says, and recycling rates are sure to go up. That will raise impurity levels too –not infinitely, but to a steady-state level. However, small changes in the recycling rates, particularly at higher levels, can entail significant changes in the steady-state levels, which may end up too high.

Change will happen fast but can be mitigated

Løvik and Müller were also able to use their model to estimate how quickly the impurities in the system could jump up to their equilibrium levels – and found that in the US, anyway, this time to reach a new higher level of impurities could be as short as two years.

That matters because it doesn’t give recyclers or can manufacturers much time to adjust to changes in the recycling mix, the researchers say.

But that is the benefit of the new study, because it gives the recycling and can manufacturing industry a glimpse into the future so they know what kinds of problems might lie ahead.

And, they can take steps to cut down on the impurity levels so that this looming problem doesn’t become a problem.

For example, “before re-melting the cans they can remove the lacquer,” Løvik said. “Or if they have objects other than cans that end up in the scrap, it is better to get rid of as much of these objects as possible before they remelt the material. Once the impurities are in the molten metal it is too late.”