THIS ARTICLE/PRESS RELEASE IS PAID FOR AND PRESENTED BY the Norwegian University of Life Sciences (NMBU) - read more

How robots find the best food

Robots that pick the finest berries, and sensors that find the best and healthiest raw produce. New technology will provide us with better food at cheaper prices.

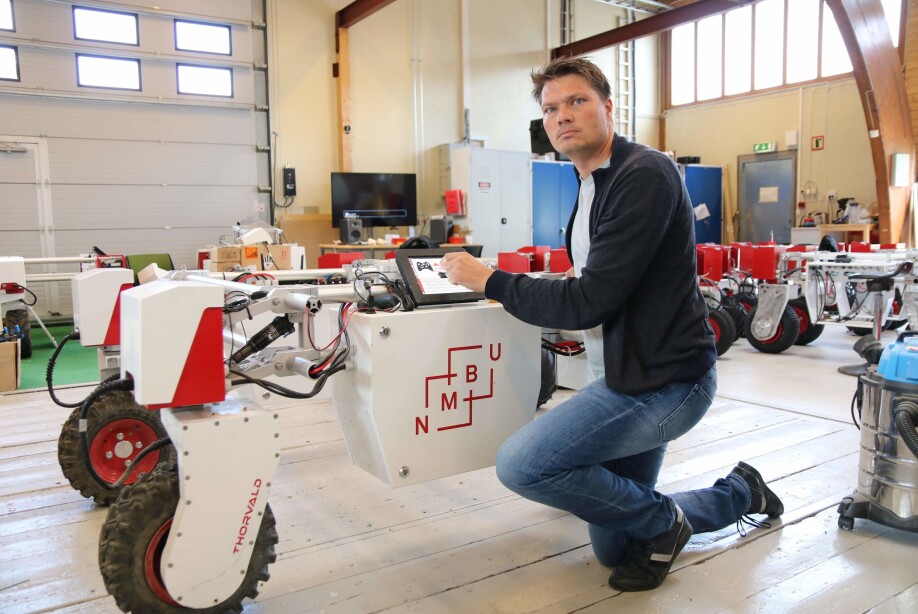

Diseased plants result in bad food. Robots are now learning how to keep plants healthy, ensuring they get the right nutrients and making sure that fruits and vegetables are picked when they are at their best. “In time, robots will probably be doing as many of the tasks as possible that need to be done out in the fields,” says Pål Johan From.

Food robots

He is a professor at the Faculty of Science and Technology at NMBU. He is working on a project that focuses on increasing digitalisation within food production.

Not only will it improve the quality of food, it will also make it cheaper and ensure that less is wasted. DigiFoods, as it is called, will develop smart sensor solutions to check the quality of food both on farms and in factories.

Pål Johan From’s job is all about robots. He wants to see how the robots can make the new sensors better, and he also wants to find out how the sensors can get the robots to do a better job. This will result in robots that can detect disease and determine when it is best to harvest the food.

“For example, we make autonomous robots that operate out in the fields. We can equip them with a lot of different sensors to measure as much as possible and find out more about what is happening in the fields,” he explains.

Sugar and fertiliser

The scientists have been working a lot with strawberries. The robots can find out when the berries are ripe and should be picked, detect disease and see if any of the berries are damaged. However, they are now going to start measuring a lot more. The sugar content, for example. The colour of strawberries is usually the best indicator of when they are ready to be picked. However, this isn’t always the case. A robot that measures the sugar content of strawberries can see much more than we can.

Here is another example: Are plants getting enough nutrients, or do they require more fertiliser? Or do they need to be sprayed, perhaps?

“Currently, we are working on robots that will pick strawberries and treat plant diseases. Once robots are out doing that job, we need to attach as many sensors as possible and measure as much as possible so that we can operate farms in the most efficient manner,” says From.

“The majority of time and resources is spent on autonomy. In other words, getting the robot to operate by itself. We use machine learning and artificial intelligence to make robots understand what to do and how to move,” he explains.

Healthier and better

The purpose of DigiFoods is exactly what it sounds like: To digitalise Norwegian food production. Better information enables the better utilisation of raw produce. It also ensures that food, and therefore people, becomes healthier. When we know exactly what affects quality, all the way from farm and fjord to fork, it is then possible to learn from it, produce better food and make the whole process more sustainable.

70 to 75 percent of the price of a food item is the cost of producing the raw produce. Therefore, digitalisation can make good food cheaper. Furthermore, the robots and sensors can help us to throw away less food because the quality improves and the food has a longer shelf life.

DigiFoods is operated as a centre where scientists and industry collaborate. Nofima leads the centre and is working with scientists from Germany, Spain and the UK - as well as Ås. In addition, a wide range of food manufacturers and technology suppliers are part of the team.

Cheaper than people

Finally: Isn’t it going to be expensive making robots that are going to cultivate relatively cheap berries, potatoes and vegetables?

Not at all:

“The technology is certainly going to be cheaper than paid labour. For a high-cost country like Norway, it will be a great advantage,” says Pål Johan From. And: Agriculture is struggling to get enough people to do these jobs, especially now that the coronavirus has closed the borders during certain periods.

References:

Ya Xiong et.al.: A Fully Automated Robot for the Preparation of Fungal Samples for FTIR Spectroscopy Using Deep Learning. IEEE, 2019. Doi.org/10.1109/ACCESS.2019.2941704

Ya Xiong et.al.: A Laboratory-Built Fully Automated Ultrasonication Robot for Filamentous Fungi Homogenization. SLAS Technology, 2019. Doi.org/10.1177/2472630319861361

———

Read the Norwegian version of this article at forskning.no

See more content from NMBU:

-

Shopping centres contribute to better health and quality of life

-

We're eating more cashew nuts – and the consequences are serious

-

Do young people with immigrant parents have better health?

-

Who’s picking your strawberries this summer?

-

Can coffee grounds and eggshells be turned into fuel?

-

Rising housing costs fuel inequality in Norway