An article from Norwegian SciTech News at NTNU

The Archbishop’s mint

The medieval coin workshop found in Trondheim is the world’s best preserved. Now scientists have reconstructed the entire coin-making process.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

Medieval Trondheim, early 1500s: A mint master and his apprentice have been up since the break of dawn. As the day draws to its end, they are sitting at a bench in the workshop, ready to strike coins.

They have already analysed the chemical composition of the silver items to be melted down and made into the coins. They have made the right coin alloy: 30 per cent silver and 70 per cent copper. They have cast rods, hammered them flat, cut them in pieces, and made the pieces round.

Then, after being weighed, adjusted and dipped in an acid bath to make them shiny, the coins are ready for striking with the Archbishop’s own dies.

For these are Archbishop Gaute Ivarsson’s coins, which King Hans of Denmark, Norway and Sweden has given him the right to mint. The bishop is a man of great political and ecclesiastical power. He leads the Norwegian Council of the Realm, and is an expert in increasing the Church’s holdings in the country.

What neither the archbishop, coin master nor apprentice knows is that in only a few years the walls and benches will be demolished and the fine tile floor will be covered with mud – while another bishop will have built a new workshop on the remnants of the old.

They also cannot know that there will be a third coin workshop atop the previous two – and that more than 500 years later, the surface of the ground will lie several metres higher than their own workshop floor.

The palace in flames

Trondheim, 18 August 1983: Dense smoke rises against the morning sky. The Archbishop’s Palace – a cluster of unique buildings from the Middle Ages – is in flames! The Fire Department manages to rescue the 800-year-old stone buildings, but two storehouses from the 1700s are lost – and with them irreplaceable cultural treasures.

But nothing is so bad that some good cannot come out of it. For archaeologists, the fire is a golden opportunity to explore the medieval city of Trondheim, called Nidaros. Between 1991 and 1995 almost 5000 cubic metres of soil are turned over, and the number of finds is greater than anyone could have imagined, totalling roughly 63 000 objects.

The most sensational and unexpected discoveries are the mints – three separate workshops on top of each other in the layers of soil. The best preserved lies at the bottom, which turns out to have belonged to Archbishop Gaute Ivarsson. It is a large intact workshop from the early 1500s, with a checkerboard-patterned tile floor in red and yellow, a hearth, metal pieces, pieces of coins and finished coins.

“It was a unique discovery and is a world-class attraction, in line with the Viking ships,” says numismatist Jon Anders Risvaag. “No other country can boast such an authentic coin workshop from the Middle Ages.”

The workshop is located there still, just as it was found, and is now a part of the Archbishop’s Palace Museum. But it is only recently that historians and metallurgists at NTNU have estimated the extent of coin production at the workshop, and documented how the Archbishop’s coins were actually minted.

A micro-workshop

“This was certainly both the world’s northernmost and smallest coin workshop. In European terms, its production was microscopic: probably only about 60 000 coins a year,” says Risvaag.

That may sound like more than just a little, but by the 1500s in Europe, coin production was essentially an industry: There were huge workshops with hundreds of employees, which spewed out millions of coins each year.

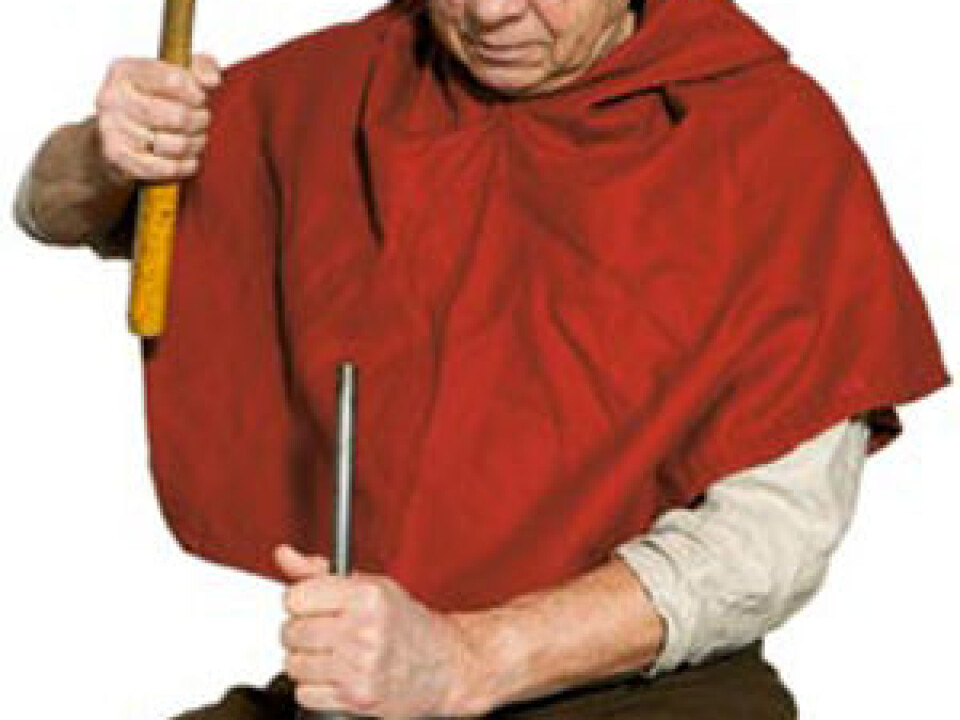

The Archbishop of Nidaros, on the other hand, was not allowed to have more than one coin master and one apprentice, the King had decided.

The estimate of 60 000 coins was based on two things: One was how many different kinds of imprints have been found stamped on different coins, and how many coins could be embossed with the top and bottom embossing dies before these would have to be replaced. Risvaag has done these calculations.

The second was based on what two men could produce in one year – if long workdays are factored in, but holy days are not.

Metallurgists made this calculation based on how long the complicated manufacturing process necessarily had to take.

“The fun is that each of our different approaches resulted in the same estimate,” says Risvaag.

The Archbishop’s means of payment

But if 60 000 coins a year amounted to almost nothing, even in little Norway, what was the point of minting them?

“The archbishop received the bulk of his income from the renting of farmlands and tithes. But minting itself was actually profitable,” says Risvaag. “There was some income to be had from collecting old coins, which were purchased at a compulsory rate that was actually lower than the silver content in them was worth.

Moreover, most fines to the church were paid in silver, so that could be used as the raw material with which to make coins. These payments were often in the form of small pieces that could not be used for larger purposes. And last but not least, the right to actually mint coins reinforced the importance of the archbishop’s political power and rank in society.”

But the most important factor, Risvaag believes, was it was convenient for the archbishop to have a marketable form of payment when dealing with foreigners and farmers. “The right to mint coins that the archbishop had received from the king stated exactly what the silver content and weight had to be for Norwegian currency. So the Hanseatic League and the Dutch traders in Bergen knew exactly what a Norwegian hvid or penny or shilling was worth,” Risvaag said.

This theory is strengthened by the fact that there has not been a single archbishop’s coin found in the city’s medieval site from before the 1550s.

Pieces put together

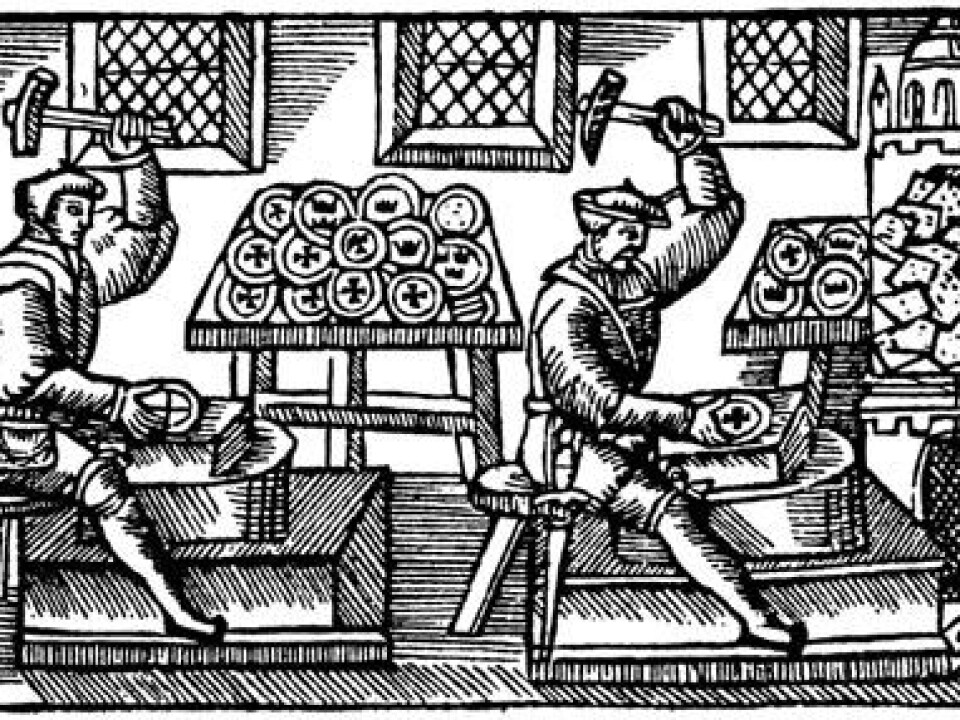

Metallurgists Otto Lohne and Pål Ulseth at NTNU have managed to reconstruct the whole process, from A to Z. Previously it was believed, for example, that the metal that was melted for coins was spread out on a plate and then stamped out, much like when you make flat cookies. But by using a microscope that shows the microstructure of the metal, researchers have now seen that the coins must have been cast in the form of a rod.

“We could also see that the rod could not have been cast in an iron form, but was cast either in soapstone or in sand,” explains Lohne.

The metallurgists have tested both metal pieces from the workshop and alloys they have created themselves, to figure out how the process worked. They have also tested all the production steps in their own laboratory.

One of the results of the research was that the exhibition around the old yard had to be changed. Not all of the text was accurate after the metallurgists became involved, and not all the objects were in the right place or were described correctly.

“To find the original bits and pieces and put them together into a coherent process has never been done before us. We have been able to look over archaeologists’ shoulders,” says Lohne.

--------------------------

Read the full article in Gemini, a magasine from NTNU