This article is produced and financed by NTNU Norwegian University of Science and Technology - read more

New nanomaterial to replace mercury

Ultraviolet light is used to kill bacteria and viruses, but UV lamps contain toxic mercury. A newly developed nanomaterial is changing that.

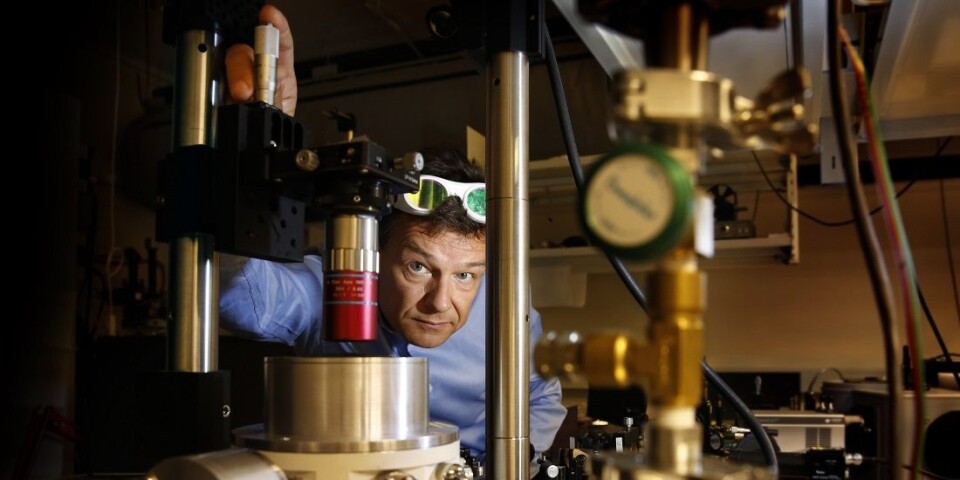

The nano research team led by professors Helge Weman and Bjørn-Ove Fimland at NTNU’s Department of Electronic Systems has succeeded in creating light-emitting diodes, or LEDs, from a nanomaterial that emits ultraviolet light.

It is the first time anyone has created ultraviolet light on a graphene surface.

“We’ve shown that it’s possible, which is really exciting,” says PhD candidate Ida Marie Høiaas, who has been working on the project with Andreas Liudi Mulyo, who is also a PhD candidate.

“We’ve created a new electronic component that has the potential to become a commercial product. It’s non-toxic and could turn out to be cheaper, and more stable and durable than today’s fluorescent lamps. If we succeed in making the diodes efficient and much cheaper, it’s easy to imagine this equipment becoming commonplace in people’s homes. That would increase the market potential considerably,” Høiaas says.

Dangerous – but useful

Although it’s important to protect ourselves from too much exposure to the sun’s UV radiation, ultraviolet light also has very useful properties. This applies especially to UV light with short wavelengths of 100-280 nanometres, called UVC light, which is especially useful for its ability to destroy bacteria and viruses. Fortunately, the dangerous UVC rays from the sun are trapped by the ozone layer and oxygen and don’t reach the Earth. But it is possible to create UVC light, which can be used to clean surfaces and hospital equipment, or to purify water and air.

The problem today is that many UVC lamps contain mercury. The UN’s Minamata Convention, which went into effect in 2017, sets out measures to phase out mercury mining and reduce mercury use. The convention was named for a Japanese fishing village where the population was poisoned by mercury emissions from a factory in the 1950s.

Building on graphene

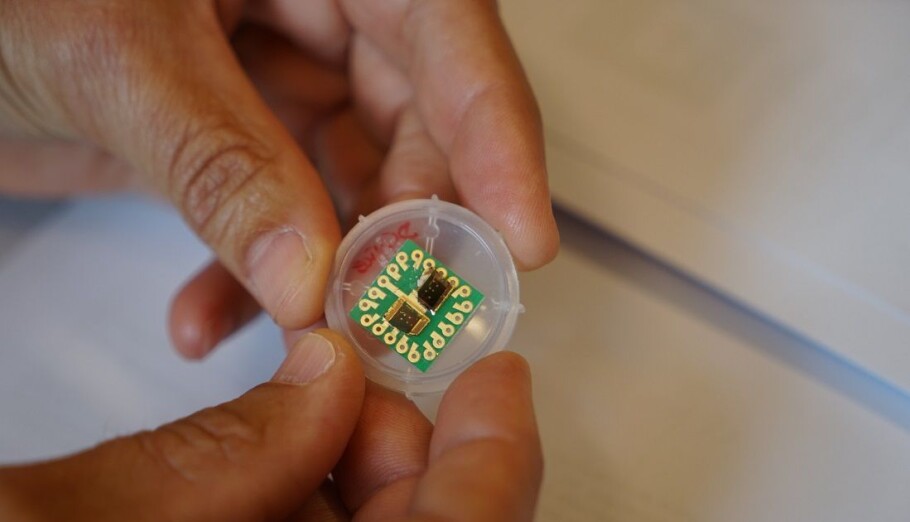

A layer of graphene placed on glass forms the substrate for the researchers’ new diode that generates UV light.

Graphene is a super-strong and ultra-thin crystalline material consisting of a single layer of carbon atoms. Researchers have succeeded in growing nanowires of aluminium gallium nitride (AlGaN) on the graphene lattice.

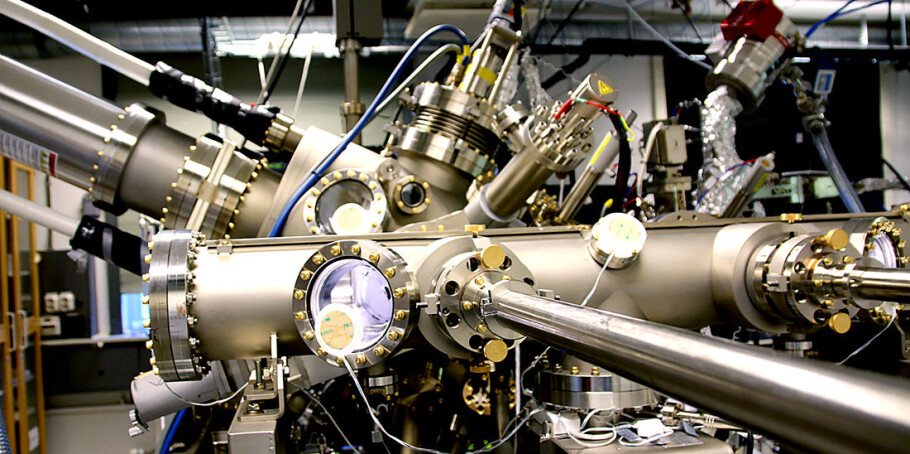

The process takes place in a high temperature vacuum chamber where aluminium and gallium atoms are deposited or grown directly on the graphene substrate – with high precision and in the presence of nitrogen plasma. This process is known as molecular beam epitaxy (MBE) and is conducted in Japan, where the NTNU research team collaborates with Professor Katsumi Kishino at Sophia University in Tokyo.

Let there be light

After growing the sample, it is transported to the NTNU NanoLab where the researchers make metal contacts of gold and nickel on the graphene and nanowires. When power is sent from the graphene and through the nanowires, they emit UV light.

Graphene is transparent to light of all wavelengths, and the light emitted from the nanowires shines through the graphene and glass.

“It’s exciting to be able to combine nanomaterials this way and create functioning LEDs, says Høiaas.

Multi-million dollar market

An analysis has calculated that the market for UVC products will increase by NOK 6 billion, or roughly US $700 million between now and 2023. The growing demand for such products and the phase- out of mercury are expected to yield an annual market increase of almost 40 per cent.

Concurrently with her PhD research at NTNU, Høiaas is working with the same technology on an industrial platform for CrayoNano. The company is a spinoff of NTNU’s nano research environment.

Use less electricity more cheaply

UVC LEDs that can replace fluorescent bulbs are already on the market, but CrayoNano’s goal is to create far more energy-efficient and cheaper diodes. According to the company, one reason that today’s UV LEDs are expensive is that the substrate is made of costly aluminium nitride. Graphene is cheaper to manufacture and requires less material for the LED diode.

Høiaas believes that the technology needs to be improved quite a bit before the process developed at NTNU can be scaled up to industrial production level.

Among the issues that need to be addressed are conductivity and energy efficiency, more advanced nanowire structures and shorter wavelengths to create UVC light. CrayoNano has made progress, but results documenting their progress have not yet been published.

“CrayoNano’s goal is to commercialize the technology sometime in 2022,” says Høiaas.