THIS CONTENT IS BROUGHT TO YOU BY Nofima The Norwegian Institute of Food, Fisheries and Aquaculture Research - read more

Fish may turn yellow if frozen too fresh

Researchers have found that freezing fish at the wrong moment could lead to surprising quality problems.

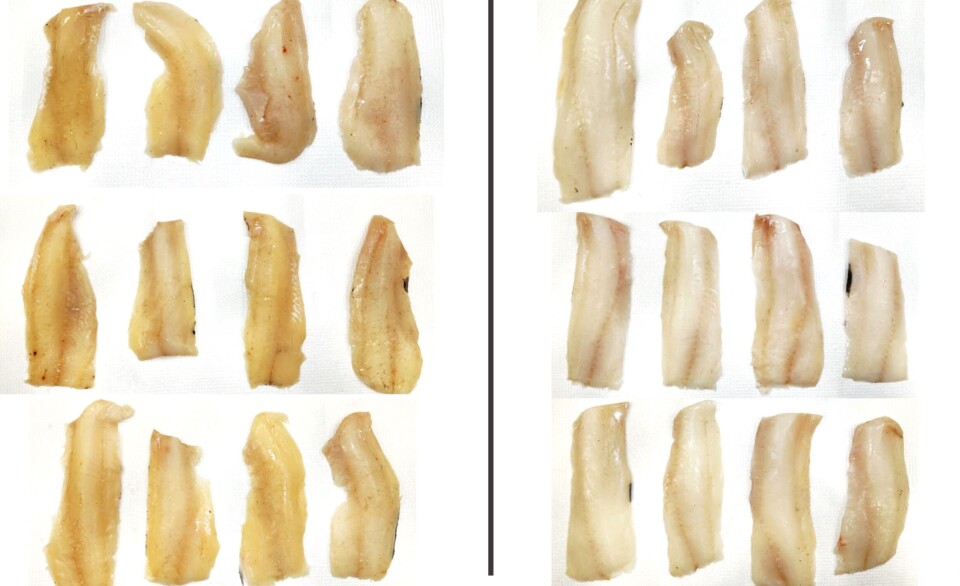

We often think 'the fresher, the better' when it comes to food – especially seafood. But the photo above tells a different story: haddock that was processed and frozen before rigor mortis set in (pre-rigor) consistently turned yellow after just 20 weeks in frozen storage.

“Yellowing caused by ‘rigor energy’ has not been described in scientific literature. It's likely that the industry has not been fully aware of how significant this can be,” says Nofima researcher Svein Kristian Stormo.

By contrast, haddock frozen after rigor mortis set in (post-rigor) showed no signs of discolouration.

Drip loss and quality

Researchers wanted to find out how the timing of freezing affects yield, quality, and consumer appeal of cod and haddock.

They compared fish frozen pre-rigor, in-rigor, and post-rigor. The researchers measured thawing loss, drip loss, and sensory qualities such as texture and colour after storage.

Project leader Svein Kristian Stormo, one of Norway’s leading experts on freezing and thawing, expected liquid loss would prove the most interesting finding.

“But I was wrong. What we in technical terms call thawing and drip loss of the raw material is indeed highly important to document. But the most surprising and interesting result was the discolouration,” he says.

A financial risk for the industry

Both liquid loss and discolouration are negative for consumers – and costly for producers.

“The challenge is twofold. There's major focus on quality – on freezing the raw material as fresh as possible. But in this case, that very approach causes greater challenges with increased liquid loss and discolouration. It's important that the industry is aware of this problem and, in the long term, finds the best solutions to minimise such effects,” says Stormo.

Historically, much of the fish frozen onboard vessels was not pre-rigor at the time of freezing. But opportunities to freeze pre-rigor raw material seem to be increasing.

“This is due to new routines with smaller hauls, better onboard handling, as well as an increase in the proportion of live deliveries to land-based facilities. In addition, cod farming will bring pre-rigor raw material handling further into focus,” says Stormo.

With greater emphasis on producing high-quality frozen raw material comes the need for fundamental knowledge of how rigor status affects raw material during freezing.

“In the first instance, it will be useful to conduct thorough documentation through controlled trials with both cod and haddock. These should monitor the effect that varying degrees of freshness have on raw material during freezing and frozen storage,” he says.

Timing is key

When it comes to liquid loss – and thus also weight and profit – the experiments clearly showed that there may be good reasons to wait until the fish has passed the first phase of rigor before being frozen.

But it is equally important to carefully monitor the quality of the raw material.

The results show that freezing pre-rigor raw material leads to significantly higher liquid release upon thawing.

"This applies to both haddock and cod, but in our experiment, the effect with haddock disappeared after eight weeks of frozen storage. With cod, however, the increased liquid loss persisted throughout an entire year of frozen storage,” the researcher explains.

Stormo notes that delaying freezing is one solution to avoiding this effect. But waiting too long introduces other problems.

“For quality and practical reasons, it is essential to establish the optimal point in time for freezing,” he says.

Reference:

Nofima report: Effekt av rigor-status før innfrysing for råstoff av torsk og hyse (Effect of rigor state before freezing of cod and haddock raw materials), 2025.

This content is paid for and presented by Nofima The Norwegian Institute of Food, Fisheries and Aquaculture Research

This content is created by Nofima's communication staff, who use this platform to communicate science and share results from research with the public. Nofima is one of more than 80 owners of ScienceNorway.no. Read more here.

More content from Nofima:

-

Red algae grown in wastewater from fish-farming facilities could become sustainable salmon feed

-

Pumpkins are good for more than just Halloween decorations

-

This is how temperature affects a salmon's health and growth

-

Study: Omega-3 and zinc is a powerful duo for salmon

-

Is it better if food is packaged in plastic or paperboard?

-

Researchers make healthy salmon feed from polluting CO₂