An article from Norwegian SciTech News at SINTEF

Office buildings from the 80's go zero-emission

Two Norwegian office buildings have been renovated and represent Northern Europe’s first zero-emission buildings of their type. These are only the first of several.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

Powerhouse Kjørbo is the name of the project, whose objectives have been to reduce energy consumption and emissions from materials to a minimum, and to create a building capable of supplying its own energy requirements.

The concept uses solar cells to produce electricity and ground source heat pumps for heating. The two buildings can generate more than 200,000 kWh annually using solar cells mounted on their roofs and on the parking garage.

“These are zero-emission buildings according to the definitions we have formulated,” says Birgit Risholt at SINTEF Building and Infrastructure.

Advanced technology and passive systems

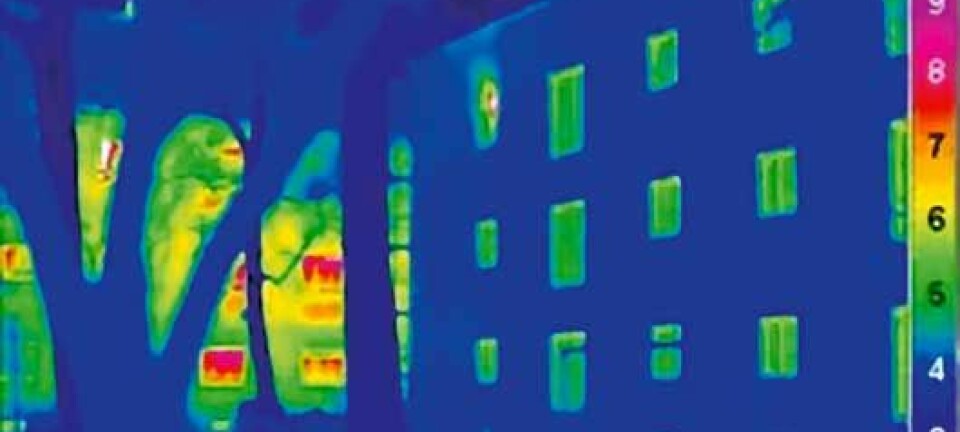

The engineering is a combination of advanced technology and passive systems to ensure efficient functioning.

For example, the building has extremely low energy consumption thanks to good insulation and partially natural ventilation systems: The stairways are used to convey large volumes of ventilating air between the floors, while thermal mass is built into the structure to reduce cooling requirements in summer. In addition, heat is injected into the ground during the summer through the drill holes made for the ground source heat pump. The energy is stored here and can be used to heat the building during the autumn.

The first of several pilot buildings

Since 2009, 22 Norwegian industrial partners have collaborated with research scientists at The Norwegian University of Science and Technology (NTNU) and SINTEF to develop systems capable of producing buildings with zero emissions. The work has been carried out within the framework of the Zero Emission Buildings Centre (ZEB), which is one of eleven centres researching into renewable energy.

"The new concepts studied are based on everything from new materials and technical solutions to user behaviour," says Risholt.

The renovation of two 80's office buildings in Sandvika, just outside of Oslo, is the first project to be completed. Later this year, several other projects will be completed elsewhere in Norway.

Close collaboration

According to Risholt, what is special about the ZEB pilot projects is the way the planning process is managed.

The work takes the form of workshops in which all technical fields and all participants are represented. This is what ensures a good result and a common understanding of what is necessary to achieve a zero-emission building.

“Traditionally it is the owner of the building who makes the decisions, followed by the architect and finally the engineer, but here everybody comes together from the outset to look at what is needed to realise a zero-emission building."

"How should the building’s geometry be? Which energy supply concept do we need for this to function? How can we optimise and reduce materials consumption? These are the sort of questions which form the themes of the workshops,” explains Risholt.

Untraditional concepts

When experts from different technical fields collaborate, untraditional concepts are the result – such as the cladding of the office building in Sandvika with charred timber.

“The use of recycled materials and materials produced using little energy is beneficial with regard to the building’s overall emissions and life-cycle. And by not using the usual painted wooden cladding we avoid not only the use of chemicals in materials but also a lot of maintenance. Charred wood is a completely new concept in Norway,” says Risholt.

The architectural concepts also demonstrate a common understanding of optimisation and zero emissions. Here, the use of metals is reduced in favour of more wood, and glass surfaces are increased in area to provide more daylight and reduce the need for electric lighting.

------------

Read the Norwegian version of this article at forskning.no