An article from Norwegian SciTech News at SINTEF

Future work clothes will monitor your health

Sensors attached to the clothes can keep tabs on the stress level and body temperature of people who work under extreme weather conditions.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

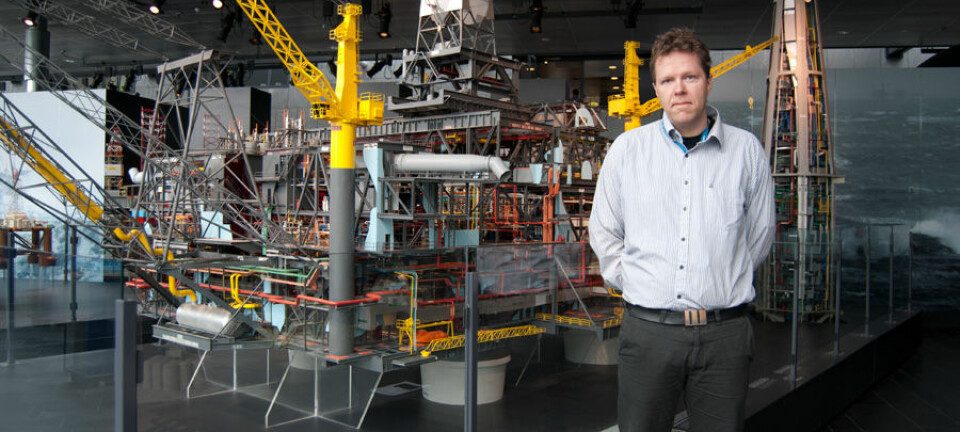

Wind, seawater and temperatures well below freezing point. This is the working environment for roughnecks working on oil and gas installations in the Arctic.

This is why research scientists at SINTEF are developing a jacket with built-in sensors. It will monitor both body temperature and workers’ activity, and may become a useful tool for supporting decision-making.

Real time measurements of workers’ physiological stress will clearly indicate when it’s time to finish work for the day. At present, temperature and wind measurements are the only indications of whether it’s safe to work in locations under extreme weather conditions, such as on the island of Melkøya off the coast of Finnmark.

“The development of this jacket is part of the ColdWear project, on which we have been working since 2008. We have performed tests in our climate chamber to obtain physiological data showing how extreme temperatures affect the performance of the human body,” says Øystein Wiggen, a physiologist and research scientist at SINTEF Health Research.

He uses this knowledge to develop new products, including specially-developed clothing both for athletes and personnel working in extreme environments.

A sensor on your arm

The jacket has been created in SINTEF’s laboratories and is equipped with built-in sensors. The garment, which as yet only exists as a demonstration model, measures hand temperature and humidity on the inside and outside of the jacket sleeve. It also monitors the wearer’s level of activity.

This will provide research scientists with important indicators of the conditions under which work is being carried out, and of how the wearer is coping. Most recent experiments have consisted of checking the sensors in the jacket by comparing them with a set of external sensors in the physiology laboratory.

“So far the measurements look promising. We can see that the sensors in the jacket and those we use for control measurement record approximately the same temperatures, even when the temperature in the environment fluctuates. We also see that the closer a sensor is to the body, the more stable the measurements become, which is natural, since the body regulates its own temperature,” says Wiggen.

The tests also show that in cold weather, the temperature measured on the outside of the jacket is affected slightly by the temperature of the test person. In other words, the outside sensor shows a slightly higher temperature than ambient. This must be taken into account if the jacket is to be used to decide whether it is too cold to work.

Sensitive equipment for tough conditions

While health researchers have been responsible for the physiological part of the research, scientists at SINTEF ICT have arranged the integration of the electronics into the jacket and the development of the sensor module itself, known as “IsenseU”, which actually measures more than just temperature.

The jacket contains the IsenseU module, which consists of control electronics, a wireless transmitter and a battery, as well as several sensors. It is also possible to connect two optional external sensors, provided they have a standard communication protocol.

“In other words, the sensors to be connected must 'speak the same language' as the sensor module and the receiver unit. This system can be used in many contexts. For example, we also use IsenseU to monitor physiological parameters and motion in patients during walking rehabilitation,” Senior Research Scientist Trine M. Seeberg explains.

In this case, though, the sensors will also be used to monitor personnel working in extreme environments.

Among other things, the jacket contains an activity sensor which measures motion, rotation and direction. It consists of an accelerometer, a gyroscope - which is sensitive to rotation - and a digital compass.

“This enables us to monitor a worker’s body position and movement in great detail and we can easily see whether the person is stationary or active, as well as measuring temperature, humidity and perspiration,” says Seeberg.

The jacket can also potentially measure phenomena such as vibrations. This can be valuable for gauging the strain experienced by workers using large drills and other machinery, while the sensors in the jacket sleeve record air humidity and temperature.

The jacket communicates with its surroundings via Bluetooth Smart, the Bluetooth of the future, which potentially requires very little energy, resulting in extended battery life.

"The data can, for example, be sent to a smartphone or PC, and thence through a mobile network to a control room,” Seeberg explains.

Tough demands on sensitive sensors

Integrating the advanced sensors into a jacket designed to withstand both cold and rough treatment has been a challenge:

The requirements are conflicting: the sensors have to be in contact with both air and skin, but at the same time they need to be protected from rough treatment. The cables also have to be flexible because the jacket must not interfere with movement.

The scientists have tackled these challenges in two ways: Among other things, they have used a sensor which does not need to be in contact with the skin itself in order to measure its temperature. Instead, it can “see” the surface temperature of a worker’s hand. The wiring has been created using thread with conductive properties which can be woven into the textile and then bent and stretched in all possible directions.

To withstand demanding weather conditions and rough treatment, the external temperature and humidity sensors are packed well into the textile. The result is robust and washable and provides a free range of movement while enabling moisture to reach the sensor.

Individual variations

Reliable measurements are essential if the technology is to be of any use, but isn’t the experience of cold different from person to person?

“It’s true that there are individual variations in whether some people feel cold or find the temperature unpleasant. For example, we know that women often feel the cold before men do,” Øystein Wiggen points out.

“The idea with equipment like IsenseU is to obtain objective measurements which can be used to support decision-making by a supervisor or control room staff. In my experience, many workers push themselves beyond stipulated limits without feeling discomfort."

In such situations, the average worker may be so determined to get the job done that his fingers become cold and lose their dexterity, with the result that screws are not fitted correctly, leading to increased risk level some time in the future.

“We may well have to use a sort of traffic-light system in such situations, in which green means “OK”, yellow means “take care” and red indicates that there is danger afoot,” says Wiggen.

-----------------------

Read the Norwegian version of this article at forskning.no