An article from Norwegian SciTech News at SINTEF

Damaged metal surfaces repair themselves

A coating filled with tiny lubricant capsules could come to the rescue when metal surfaces dry out and friction builds up.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

A ball bearing – or a slide bearing around an axle – needs lubricating at all times.

If a leak causes the lubrication in the bearings of large machines to dry out, there can be huge cost implications. Metal surfaces can grate against each other and seize up, in the worst case resulting in a total write-off.

Wind turbines, for example, have high maintenance costs, of which overhaul of their mechanical components alone accounts for 30 per cent.

Other cost savings for the industry involve energy consumption, personnel, lubrication expenses and maintenance and spare parts.

Lubrication in tiny capsules

As part of a project at the Gemini Tribology Centre (friction, wear, lubrication), a group of researchers from SINTEF and the Norwegian University of Science and Technology (NTNU) have spent two years building ground-breaking expertise in coatings and thermal spraying.

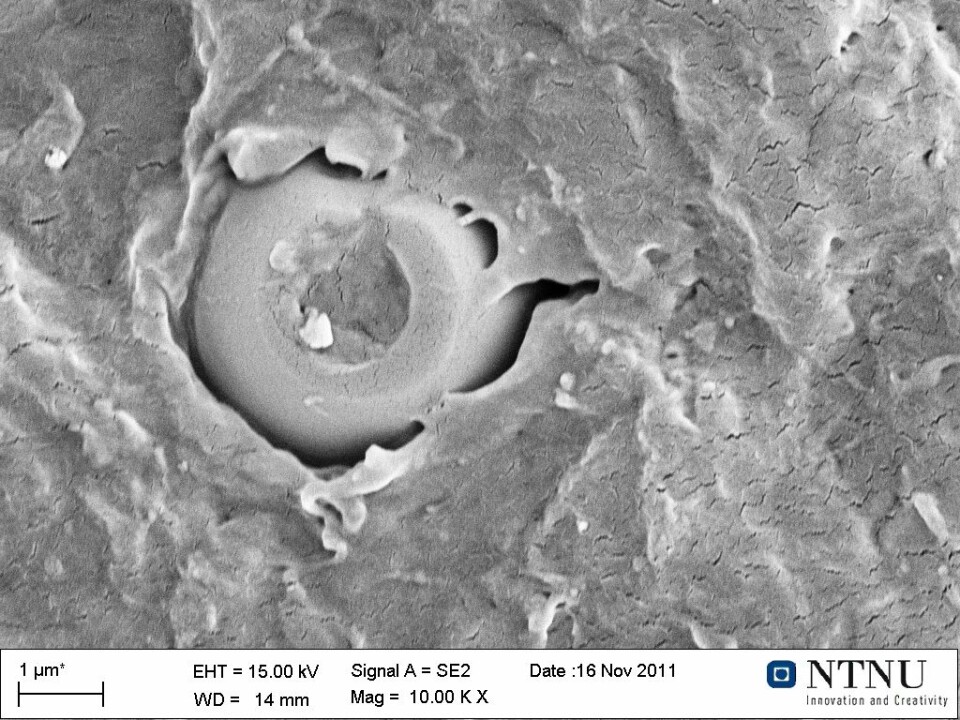

The researchers are now testing whether it is possible – where two metal surfaces are in contact with each other – to apply a coating to the surfaces formed of hard particles and capsules filled with liquid lubricant.

“We apply the lubricant using a thermal spray technique, where powder and capsules are fired at the surface using a flame,” says Sergio Armada of SINTEF Materials and Chemistry.

“When the metal surfaces come into contact with each other, the coating is broken down in a controlled manner, releasing the contents of the capsules, and the lubricant will then prevent further friction.”

The researchers have carried out a number of tests on slide bearings in industrial settings, in which they have measured friction on surfaces with and without the capsules.

When a coating without capsules was applied to the slide bearing, the friction coefficient was 0.7, while friction was reduced to 0.15 in bearings coated with a layer of capsules.

Industry on the lookout

The idea of self-repairing metals is not a new one. Two years ago, a metallic coating of capsules and the “electroplated layer” lubrication method was presented in the Economist magazine.

Materials researchers from Fraunhofer and the University of Stuttgart were behind the article. The disadvantage of this method was that since the lubrication was applied using electricity, it was only possible to apply a single metallic layer.

Another challenge was that the capsules in the coating were too big. Since a surface layer should preferably be only 15–20 micrometres thick, the capsules must be a fraction of this size if they are not to be released too quickly.

“In our case, the capsules must be smaller than 10 micrometres, so that they do not block the nozzles and cause problems during the spraying process. We have now created capsules as small as 2 micrometres,” says SINTEF researcher Christian Simon.

His colleague Ruth Schmid is producing capsules with an extremely low friction coefficient that could prove to provide the coating with even better tribological properties.

Many applications

“Our method has many potential applications, and is suitable for a wide range of coatings,” says researcher Sergio Armada.

“It will be possible to apply the coating to large surfaces and components, and the actual material of the coating can also be varied – from metals to polymers and ceramics.”

Armada thinks that the coating could also be used in the medical sector in hip and knee replacements. These are also places where surfaces move against each other, and grating can occur if there is not enough fluid in the joint.

Patients would therefore benefit from lubricants applied in a coating of capsules which is sprayed onto the implant before it is inserted. Nuria Espallargas and Ragnhild Aune of NTNU are working on new materials that have capsules filled with medication or antibiotics that can be released when they are needed.

The project has now come to an end, but the parties have written a project proposal and applied to the EU to be able to continue their work on thermal spraying and biocompatible coatings.