This article is produced and financed by NTNU Norwegian University of Science and Technology - read more

NTNU establishes a factory to produce coronavirus tests

NTNU researchers recently figured out a whole new method for testing people for the coronavirus. The university is now producing tests on a continuous basis, under the auspices of the Norwegian Directorate of Health. Currently 100 000 tests a day are being manufactured, with production soon likely to be scaled up dramatically.

In tandem with large sections of society being put on hold by the coronavirus pandemic, the resulting state of emergency has accelerated activity in many corona-related fields. Research and innovation, which often involve slow and painstaking processes, are among the areas experiencing a surge in activity.

The invention of the new NTNU method for testing for the coronavirus is proof that R&D can move along at a rapid clip as well. The times we are in are forcing work processes to adapt, and special permits are being issued to facilitate society’s needs.

In the space of just a few weeks, an interdisciplinary research team at NTNU has invented a whole new testing method for the coronavirus – and established scaled-up production of the tests.

“I think the coronavirus crisis has taught us something about how we have to organize ourselves in the future in order to meet different challenges,” says Magnar Bjørås. He has led the development of the new testing method from NTNU. Bjørås is a professor in NTNU’s Department of Clinical and Molecular Medicine.

Industrial-scale production

The production facilities were set up inside NTNU’s Gløshaugen campus in Trondheim. The university has become a production plant and is already supplying 100 000 COVID-19 tests a week to Norwegian university hospitals.

Planned future production will be even higher.

NTNU can currently make 100 000 tests a day. Running several production lines in parallel would make it possible to scale up to even greater production.

The fact that a university can actually become an industrial player in this way is rooted in the government’s rules related to emergency exemptions associated with the coronavirus crisis. The need for tests is huge, and finding the most effective solutions is critical.

“We’re talking about production almost on an industrial scale. It’s quite unique,” says Eivind Andersen. He and his colleagues at NTNU Technology Transfer (TTO) work to patent and industrialize inventions, in this case the COVID-19 test.

High demand

Since the outbreak of the coronavirus pandemic, the demand for testing has been enormous in Norway and the rest of the world. The lack of necessary reagents has imposed major limitations on the capacity to produce tests. Reagents are chemical substances that act like extraction kits to isolate the virus and the virus’s genetic material, RNA.

This is where the NTNU researchers’ invention comes in.

With Magnar Bjørås and Sulalit Bandyopadhyay at the forefront, researchers from the Department of Clinical and Molecular Medicine and the Department of Chemical Engineering have come together in a fruitful and interdisciplinary collaboration.

The Department of Materials Science and Engineering is also involved, and the Department of Microbiology at St. Olav’s Hospital has been an important contributor.

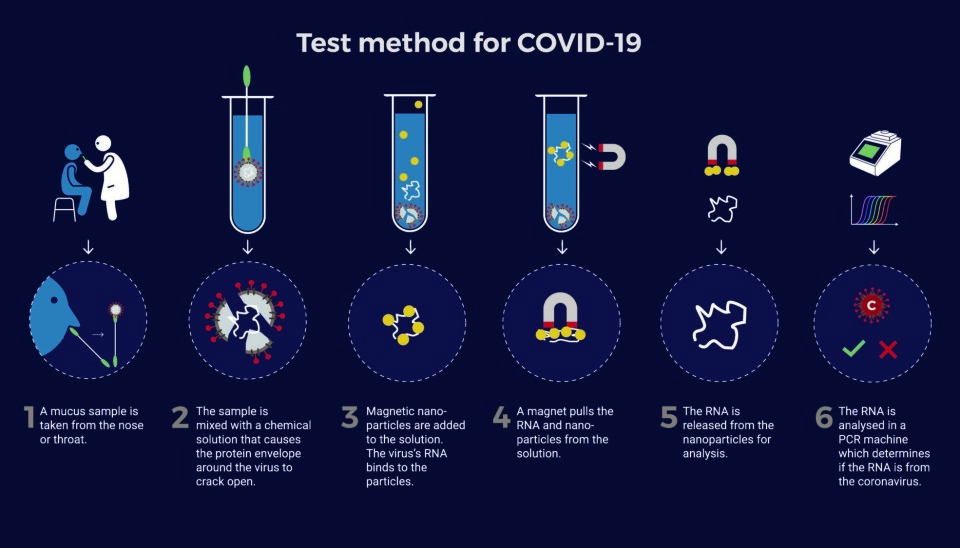

The virus’s RNA molecules lie well protected within the virus and are tightly enveloped by other molecules. Therefore, when a sample is taken from a person presumed to be infected, the first challenge is to “unpack” the virus’s RNA so that it can be analysed.

In record time, the NTNU researchers have developed a specific combination of polar solvents, buffers, salts and other chemicals to enable this separation without damaging the RNA molecule. Optimization of this chemical composition is part of the NTNU invention and allows the extraction of RNA from a small amount of virus.

Nanoparticles are important factor for test capacity

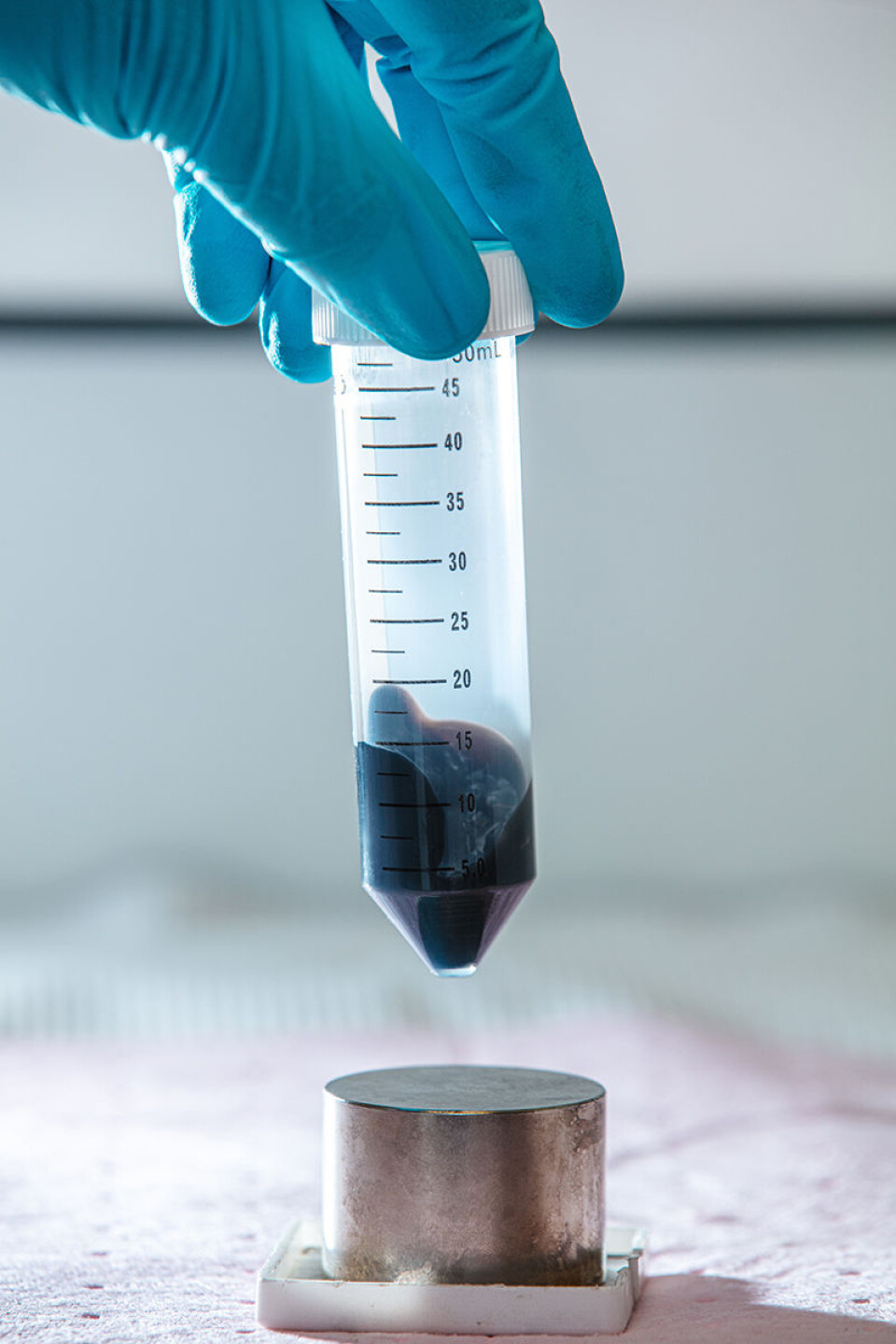

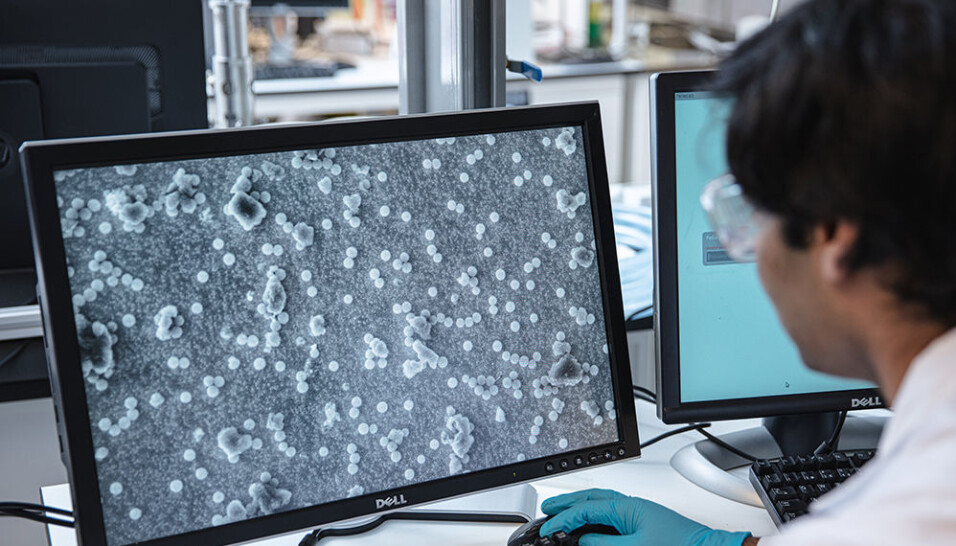

The NTNU researchers have developed a method to produce magnetic nanoparticles that can extract the released RNA of the virus into solution. The production methodology of these magnetic nanoparticles turns out to be very scalable. A single “production batch” is enough for 10 000 tests, which could be increased.

Bandyopadhyay is a key figure in the part of the invention responsible for producing the specific magnetic nanoparticles. He is a postdoc at NTNU’s Department of Chemical Engineering.

The quality and amount of the nanoparticles are essential to the new test method.

“The fact that the researchers have managed to develop a method for producing very high-quality nanoparticles – along with a scalable process to apply a silica coating that binds to the virus’s RNA – is a prerequisite for producing a big number of tests at practically an industrial scale,” says Andersen at NTNU TTO.

“NTNU’s method may prove to be both more sensitive and more scalable than other developed methods,” he says.

The inventors and researchers involved are working in overdrive 24/7. Work is now underway to involve and train more people in the production process at NTNU, and eventually additional competent professionals will be able to come in and assist the core team to ensure robust higher production.

Why is it important to test lots of people?

Multiplying the coronavirus testing capacity will provide better oversight over the spread of infection. Now that some segments of society are opening up a bit, more extensive testing will enable the health authorities to assess how easing restrictions affects the spread of the virus.

“If we can get the diagnostics up, it will be easier to monitor how the various measures are working,” said former NTNU Rector Gunnar Bovim.

In collaboration with the Norwegian Institute of Public Health, the Directorate of Health and the South-Eastern Norway Regional Health Authority, Bovim has led efforts to identify the bottlenecks in the way of expanding testing capacity. Adequate equipment and personnel to perform and analyse the tests have been limiting factors.

Right now the COVID-19 tests are being used to test health professionals with symptoms or who have been exposed to the virus, as well as particularly vulnerable people in the population. The government’s goal is for everyone who has coronavirus symptoms to be tested by the end of May.

Employees, children and parents in schools and kindergartens are a new, large target group who can be tested, according to the Norwegian Institute of Public Health, since grade schools and kindergartens re-opened this week.

The Norwegian Institute of Public Health and the Directorate of Health will continuously update the status of test criteria and further plans for testing.

Interdisciplinarity vital for solving complex problems

Many positive factors have come together to accomplish all this, and a lot of talented people have worked around the clock and with great enthusiasm. Interdisciplinarity and collaboration have been essential to the story that is evolving from day to day at tremendous speed.

St. Olav’s hospital has contributed important resources, including bioengineers who analyse corona samples in the laboratories. Their work is crucial to the diagnosis and treatment that patients receive.

The collaboration on the COVID-19 test is a good example of how new connections between different professional disciplines can help to solve social challenges in an effective way.

NTNU Rector Anne Borg emphasizes the importance of collaboration and interdisciplinarity.

“The crisis has taught us that working in an interdisciplinary way to solve complex problems is a huge advantage. When NTNU’s academic environments developed a new testing method for infection just before Easter, it was through collaboration between researchers from our medical and technology environments. Globally, too, scientists from many countries are collaborating to develop vaccines against COVID-19. We have to continue to grow this ability to work across disciplines,” says the rector.

To the question of how we can help create a better world after this coronavirus, Rector Borg responds, “NTNU is a university that has always been in close contact with business and industry and has cultivated innovation. It may be that the pandemic will lead to even clearer expectations about how we can contribute to creating new jobs.”