THIS CONTENT IS BROUGHT TO YOU BY NTNU Norwegian University of Science and Technology - read more

This filter could make electric car batteries last much longer

This new invention could make today’s electric vehicle batteries lighter, safer, and increase their range.

Car manufacturers and others who need light, safe, powerful batteries are eager to adopt lithium-sulphur (Li-S) batteries.

They store more energy, charge faster, and are safer than today’s lithium-ion batteries – they’re also cheaper to make.

Batteries with challenges

The big drawback of these next-generation batteries is that they wear out very quickly. This is because of the shuttle effect.

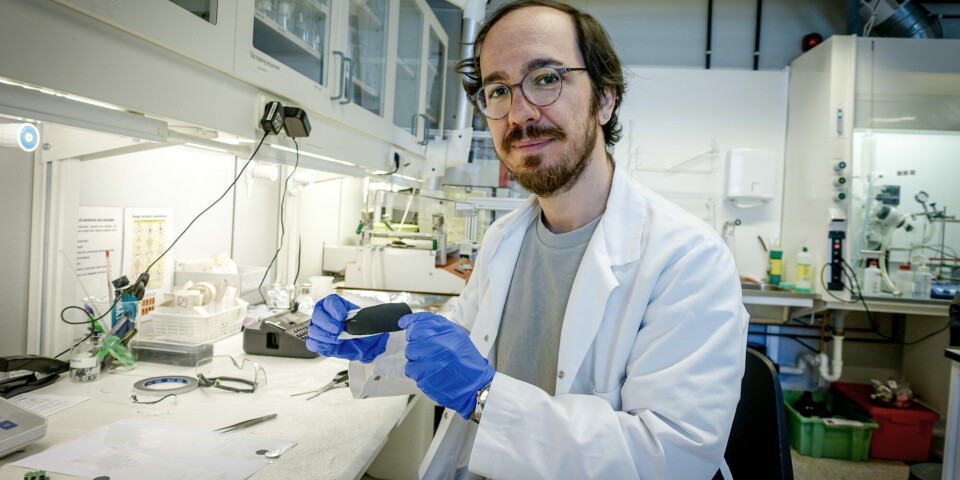

Önder Tekinalp explains that when the battery is in use, chemical substances called lithium polysulfides (LPS) form. They move between the electrodes – the positive anode and the negative cathode – in the battery.

"It's these substances that cause Li-S batteries to degrade quickly, lose capacity, and have a short lifespan,” he says. Tekinalp is a researcher at NTNU’s Department of Chemical Engineering.

This also explains why Li-S batteries are not yet used in electric cars.

New, thin, smart filter

Professor Liyuan Deng and NTNU's membrane research team have developed an ultra-thin coating with special properties that could change this. Patented through the HiSep-II project, the coating carries the same name.

Batteries also contain a separator – a barrier between electrodes that keeps them working and prevents short circuits. When the HiSep-II coating is applied, it acts as a smart filter.

While many focus on improving cathode chemistry or electrolytes, NTNU researchers turned their attention to the separator.

“The coating blocks the harmful chemical substances and allows useful lithium ions to pass freely,” says Tekinalp.

Slimmer, lighter battery pack

The lifespan of a battery is often measured in charge cycles. One cycle is one full charge and full discharge.

Lab tests show that Li-S batteries with HiSep-II can increase the number of charge cycles from 200 to 1,000 – a fivefold increase.

The battery pack in an electric car consists of many parts.

The researchers say their technology could reduce the weight of an 800-volt battery pack by over 200 kilograms. This would boost efficiency and driving range. Since the batteries use sulphur, an abundant material, they're also cheaper to produce.

A real alternative for electric cars

Tekinalp sees their research as a breakthrough that could make Li-S batteries a real option for electric cars.

“Although HiSep-II has not yet been used in electric cars, we have shown that it can handle the shuttle effect. It has been the major brake on commercial exploitation – until now,” he says.

Also at sea, on land, and in the air

“The goal is to scale up the technology and license it to an industrial partner so that it can be used in everything from electric cars to storage of green energy,” says Kristina Nydal. She is a business developer at NTNU Technology Transfer (TTO).

Nydal believes Hi-Sep-II improves battery safety and is ideal for use at sea, on land, and in the air.

“It's also an attractive and cost-effective alternative for storing energy. Especially where longevity and stability are crucial factors,” she says.

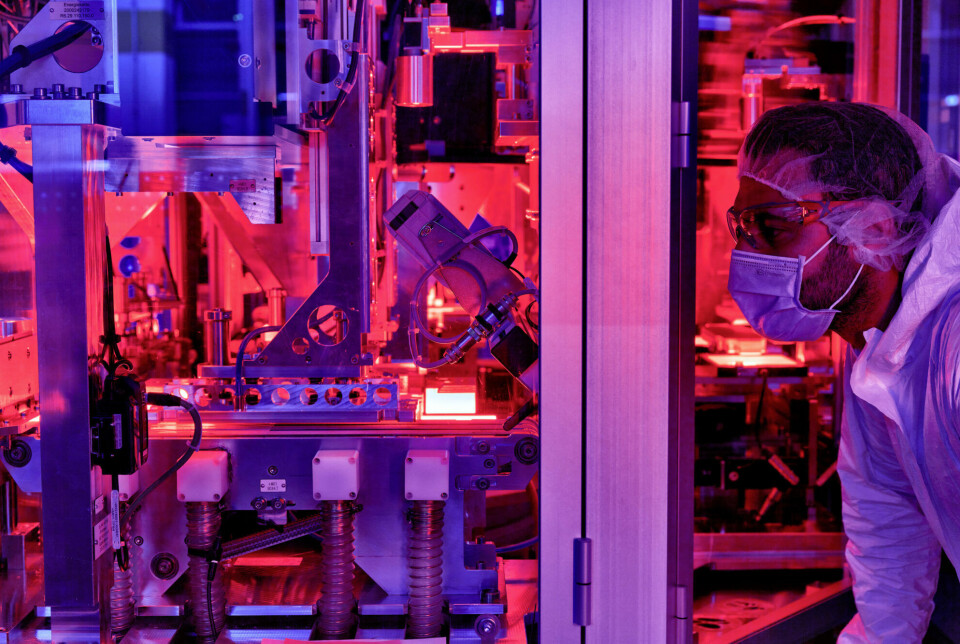

The production process is environmentally friendly, scalable, and compatible with today’s lithium batteries.

More testing required

Before the technology can enter the market, it must be tested by an independent third party. The filter has to be built into Li-S batteries, and its performance verified.

Documenting that the technology is reliable and stable in the long term is crucial. The smart filter must also be safe to produce, cost-effective, and consistently high in quality.

Batteries with benefits

Several breakthroughs in sulphur batteries have been announced in recent years. How does this research stand out?

“Many Li-S breakthroughs focus on improving cathode materials or electrolytes. The HiSep-II targets the separator, or filter, alone. It's a simpler, more scalable solution without the use of complex materials," says Tekinalp.

He adds that the production process is environmentally friendly, easy to scale up, and compatible with today's lithium batteries.

More content from NTNU:

-

Why is nothing being done about the destruction of nature?“We hand over the data, but then it stops there"

-

Researchers now know more about why quick clay is so unstable

-

Many mothers do not show up for postnatal check-ups

-

This woman's grave from the Viking Age excites archaeologists

-

The EU recommended a new method for making smoked salmon. But what did Norwegians think about this?

-

Ragnhild is the first to receive new cancer treatment: "I hope I can live a little longer"