Industrial robots now also for small companies

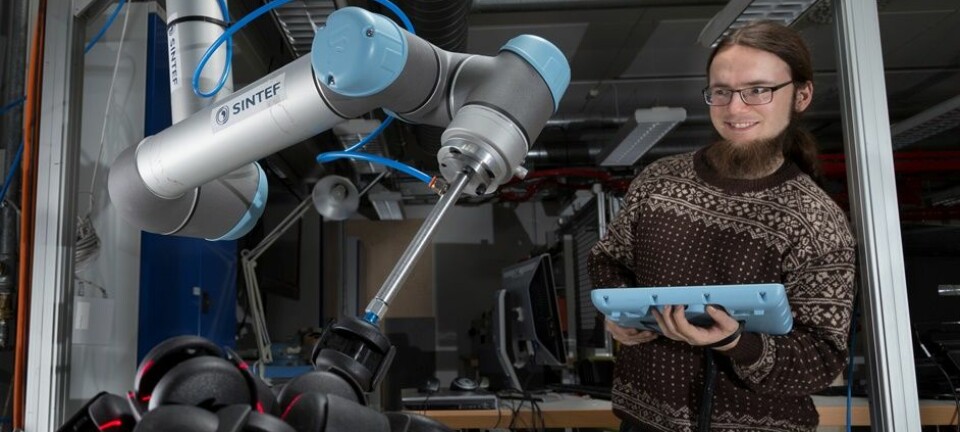

Danish scientists have developed a robot operating system that can mimic human movement. The system will make it easier for small companies to use robots, argues researcher.

Robots are expensive and difficult to program, which is why they are normally only used by large companies.

However, a new robot operating system, which can mimic some human movements, aims to make it easier for staff at small and medium-sized companies to program their robot for specific tasks.

”Assembly tasks can be carried out with traditional robot technology, but this is not appropriate for small and medium-sized businesses which cannot afford to hire a robot programmer every time they reorganise their production,” says Assistant Professor Thiusius Rajeeth Savarimuthu, PhD, of the Maersk Mc-Kinney Møller Institute at the University of Southern Denmark, who is one of the researchers behind the new operating system.

“We have therefore developed a concept in which a camera registers what the robot should do, and then it does it.”

Robot system can learn and remember

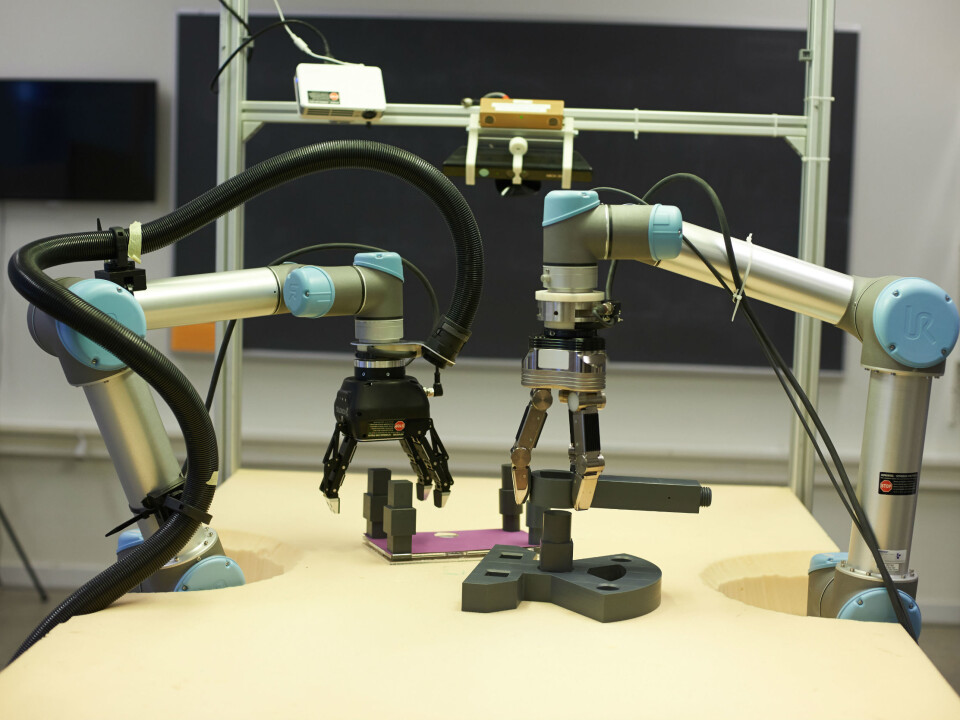

The new system has been tested on a platform with two robotic arms, where the researchers instructed the robots how to assemble various objects, and then the robots mimicked the researchers’ movements.

Our ability to observe and learn forms the basis of the new system. The robotic arms were fitted with three sets of cameras, which point towards the desk where the robots do their work.

The photos taken by the cameras are put into the new system, which processes them and converts them into motion.

In addition to mimicking human movements, the system also makes it possible for robots to remember what they see:

Assembly tasks can be carried out with traditional robot technology, but this is not appropriate for small and medium-sized businesses which cannot afford to hire a robot programmer every time they reorganise their production.

Thiusius Rajeeth Savarimuthu

”The robotic arms can remember the movement you show them and can subsequently use this movement in a variety of contexts. This means that you only need to show them a certain movement once,” says Savarimuthu.

Robot gets quicker as it learns

Since the system can remember what it learns, the robot will be able to carry out the work faster and faster the more it repeats a certain action.

“When the robot system learns a new movement, it performs it slowly at first because it needs to learn how to perform the movement correctly. But after six or seven attempts, it can run at full speed,” he says.

Important step towards cheaper robots

The system’s ability to learn and remember movements independently of a programmer is an important step towards more affordable robots, says Ole Ravn, a robot researcher at the Department of Electrical Engineering at the Technical University of Denmark, who did not take part in the development of the new system.

When the robot system learns a new movement, it performs it slowly at first because it needs to learn how to perform the movement correctly. But after six or seven attempts, it can run at full speed.

Thiusius Rajeeth Savarimuthu

”This represents a first step towards the goal where robots are better and less expensive to reprogram because you simply need to show it what to do. This project is an important contribution towards this goal,” he says.

Ravn also points out that it is currently difficult to make robots that can grasp objects that they do not know, but with the new system he believes this problem can be solved:

”This project can be used as a stepping stone towards a robot gripper that can grasp objects it does not know in advance, and if it can work in the real world, then we’re really talking about an impressive step forward.”

System cannot solve all tasks

The new robot system is part of the EU-funded project IntellAct, which aims to teach robots to understand the meaning of human movement in a production context, so that they will be able to perform tasks themselves, independently of programmers.

There are, however, limits to what kind of work the robots are able to mimic:

”There are some limitations in terms of the complexity of the tasks. For example, the objects cannot be too small for the robot to handle, so it won’t be able to thread a needle,” says Savarimuthu.

System being tested with companies

It will take a while before small and medium-sized companies can start using robots that do not require a programmer, but researchers at the University of Southern Denmark are well underway with developing systems that can benefit such companies.

Small and medium-sized companies often use production processes that are difficult to automate, but the researchers expect that the new operating system can open up new opportunities for them.

“We’re running several other projects developing similar systems for specific assembly line tasks, and some of the results from the new project will now be tested in the companies,” says Savarimuthu.

----------------

Read the Danish version of this article at videnskab.dk