Making Norway's deadliest food

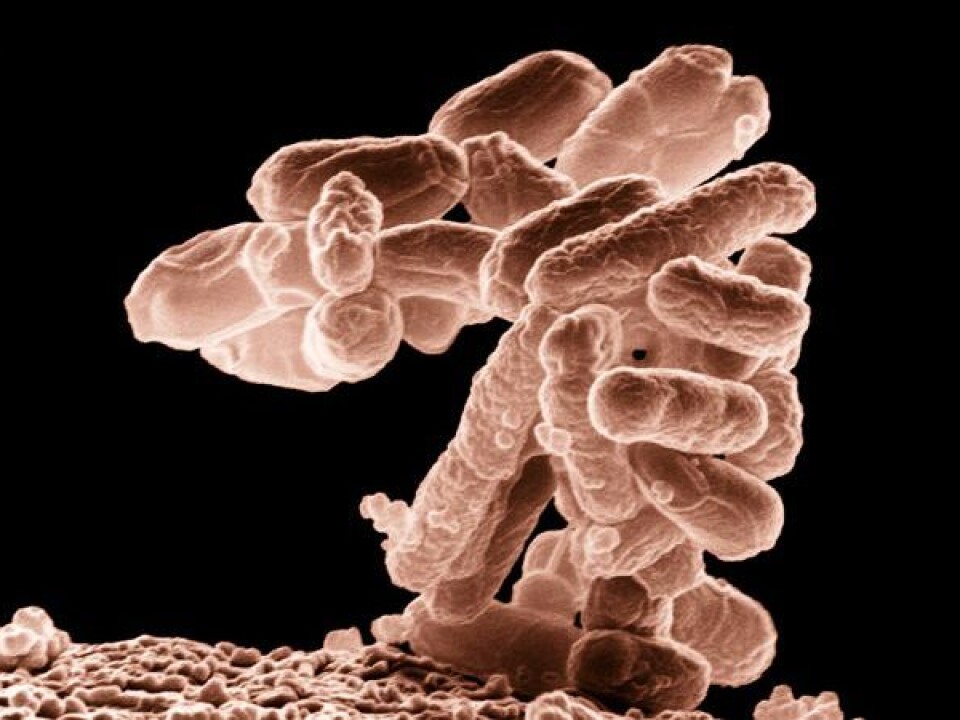

It's food, but not as we know it: a new processing plant is set to produce sausages packed with deadly E.coli and cheese full of Listeria – to save us from food poisoning.

Denne artikkelen er over ti år gammel og kan inneholde utdatert informasjon.

The only facility of its kind in Europe, the new laboratory at Ås will offer researchers the opportunity to contaminate foodstuff of every kind with pathogenic microbes.

“The pathogen processing plant will be a national resource centre, available for researchers from across Norway and abroad who wish to conduct experiments with hazardous food production,” explains Helga Næs, Research Director Food Safety and quality at the research institute Nofima - one of the partners behind the project, alongside the Norwegian University of Life Sciences and funder The Research Council of Norway.

“So far the only option available to researchers has been to use models, such as cell cultures in tubes or dishes with nutrients, to study these hazardous bacteria. However, models do not necessarily reflect what's happening on the surface of a lettuce or inside a sausage,” she points out.

The facility will open up a range of new approaches for researchers.

“It will be possible to contaminate anything from fruit to seafood with harmful and potentially lethal bacteria - following the process through production, packing and storage,” Næs adds.

Improvised sausage factory

The pilot plant, scheduled to be completed in spring 2013, is a result of experiences after an outbreak of E.coli-poisoning in 2006 where 18 people fell ill and one child died after eating contaminated smoked sausage.

The subsequent research took place in an improvised sausage factory within a sealed laboratory, in order to mimic the production process. By adding E.coli and experimenting with different recipes, varying amounts of salt and sugar, and differences in production and storing, the researchers were able to identify crucial factors.

Killing bacteria with heat, storage and high pressure

The salting, drying and souring effect of the sausage production process in itself kills off 90 to 99 per cent of unwanted bacteria. But in order to reach a safer bacterial level, additional methods such as heat treatment, long-time storage at room temperature or high pressure treatment were needed.

Although we have learnt much about how pathogens such as E.coli, Listeria and Salmonella can contaminate food, much less is known about what happens to the microbes throughout the production process.

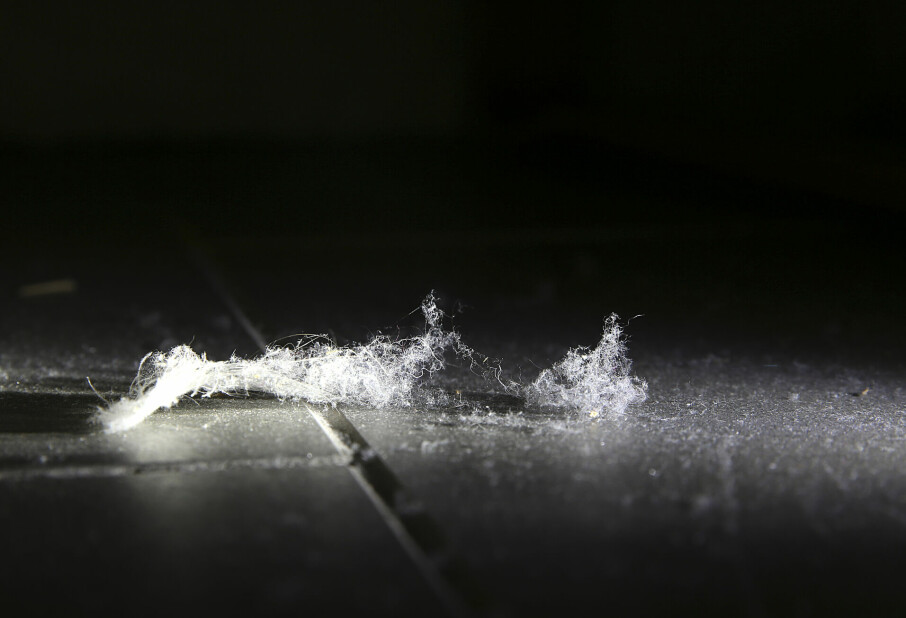

The new facility will enable researchers to explore how raw materials and products are contaminated from equipment and conveyor belts, the most effective measures to get rid of any pathogens, or the optimal way of disinfecting equipment.

'Biosafety level 3' facility

The pilot plant will have a 'Biosafety level 3' rating, the second-ranking safety level, where disease 'may have serious or lethal consequences'. The researchers will be wearing protective gear and follow strict safety regulations, locked inside sealed premises.

All access is through air locks, external air flow will be microfiltered, and low air pressure inside the plant ensures that microbes won't escape outside if there is a leak.

“No-one will be at risk by working here,” assures Næs. “On the contrary - this should be an engaging experience for the researchers, contributing towards making food safer and preventing public health hazards.”